Real-time fault detection on edge devices is revolutionizing how industries monitor equipment, prevent failures, and optimize operations with unprecedented speed and reliability. ⚡

The Rising Importance of Edge-Based Fault Detection

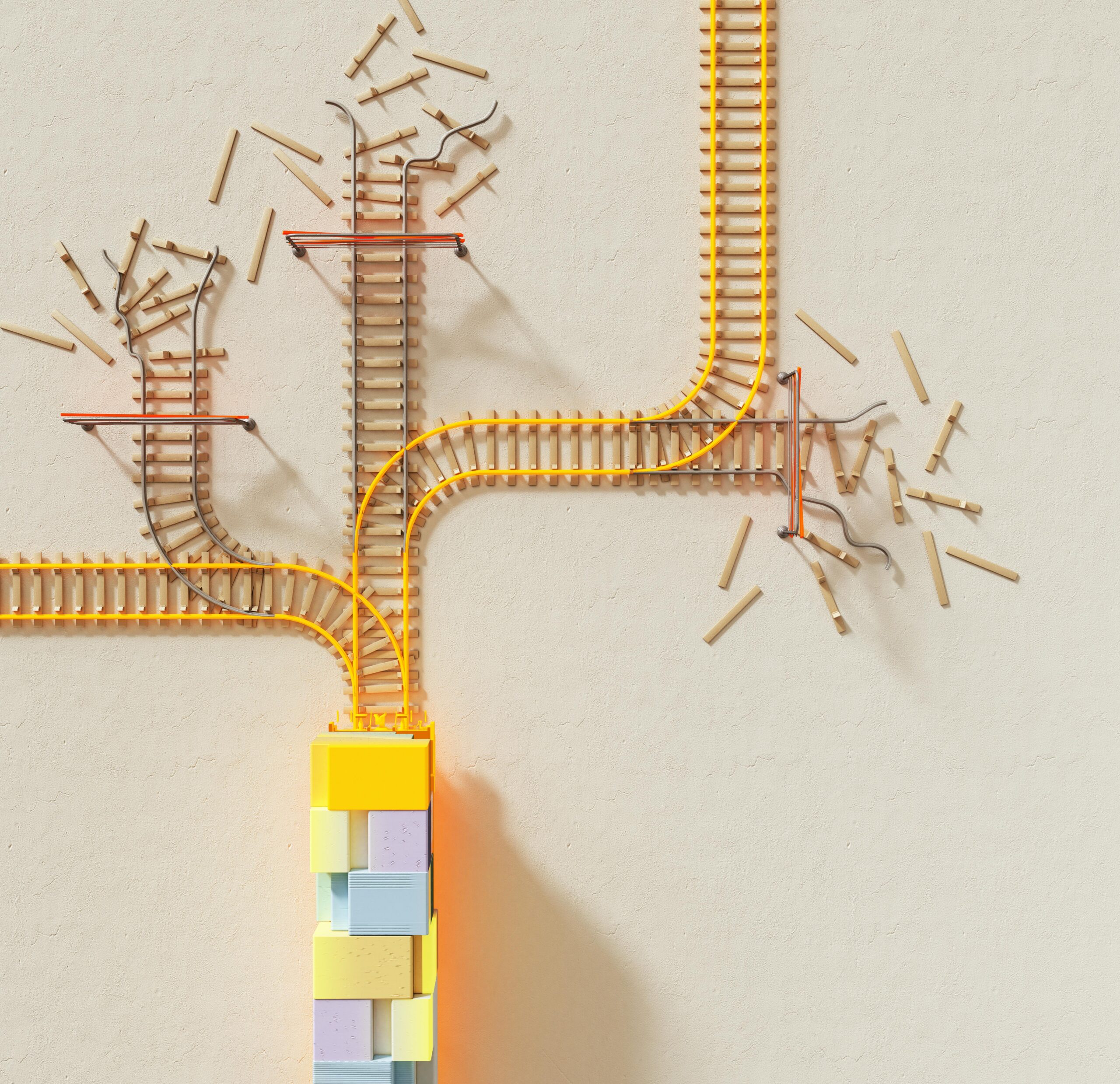

Traditional fault detection systems relied heavily on centralized cloud computing, creating latency issues and bandwidth constraints that could mean the difference between catching a critical failure and experiencing costly downtime. Edge computing has fundamentally changed this paradigm by bringing computational power directly to where data is generated—on the devices themselves.

Manufacturing plants, automotive systems, energy grids, and IoT infrastructures are increasingly deploying edge devices equipped with advanced sensors and processing capabilities. These intelligent systems can analyze data locally, identify anomalies, and trigger immediate responses without waiting for cloud processing. The result? Faster decision-making, reduced bandwidth consumption, and improved operational resilience.

The shift toward edge-based solutions isn’t just a technological trend—it’s becoming a competitive necessity. Organizations that implement real-time fault detection on edge devices report significant improvements in equipment uptime, maintenance efficiency, and overall system performance. 🚀

How Real-Time Fault Detection Works at the Edge

Understanding the mechanics behind edge-based fault detection helps appreciate its transformative potential. The process involves several interconnected components working in harmony to identify and respond to equipment anomalies instantly.

Data Collection and Preprocessing

Edge devices continuously collect data from multiple sensors monitoring variables like temperature, vibration, pressure, electrical current, and acoustic signatures. This raw data undergoes immediate preprocessing at the edge, filtering out noise and normalizing values before analysis begins.

The preprocessing stage is crucial because it reduces the computational load for subsequent analysis steps while ensuring data quality. Modern edge devices employ efficient algorithms that can handle high-frequency data streams without overwhelming limited processing resources.

Machine Learning Models on the Edge

The heart of real-time fault detection lies in sophisticated machine learning models deployed directly on edge devices. These models are trained to recognize normal operational patterns and identify deviations that indicate potential faults or failures.

Common approaches include:

- Anomaly detection algorithms that flag unusual behavior patterns

- Predictive maintenance models that forecast component failures

- Classification systems that categorize fault types

- Time-series analysis for trend identification

- Deep learning networks for complex pattern recognition

These models are optimized for edge deployment, balancing accuracy with computational efficiency. Techniques like model quantization, pruning, and knowledge distillation enable powerful AI capabilities within the constraints of edge hardware.

Immediate Response Mechanisms

When a fault is detected, edge devices can trigger immediate responses without waiting for cloud authorization. This might include sending alerts to operators, adjusting operational parameters, initiating protective shutdowns, or activating backup systems. The speed of these responses—measured in milliseconds rather than seconds—can prevent catastrophic failures and minimize damage.

Performance Benefits That Transform Operations 📊

Implementing real-time fault detection on edge devices delivers measurable performance improvements across multiple dimensions. Organizations consistently report transformative results after deployment.

Dramatic Reduction in Downtime

Unplanned equipment downtime costs industries billions annually. Edge-based fault detection systems can identify early warning signs of impending failures, enabling preventive interventions before critical breakdowns occur. Manufacturing facilities report downtime reductions of 30-50% after implementing these systems.

The ability to catch problems in their earliest stages means repairs can often be scheduled during planned maintenance windows rather than requiring emergency shutdowns. This planning capability alone generates substantial cost savings and operational predictability.

Enhanced Equipment Lifespan

Continuous monitoring and early fault detection help extend equipment lifespan by preventing minor issues from escalating into major damage. When systems operate within optimal parameters and receive timely maintenance, components experience less stress and degradation.

Industrial motors, for example, can last years longer when vibration anomalies are detected and corrected early. Similarly, thermal management issues caught promptly prevent accelerated wear on electronic components.

Improved Operational Efficiency

Real-time insights enable operators to optimize performance continuously. By understanding exactly how equipment is functioning moment-to-moment, adjustments can be made to maximize efficiency while staying within safe operating limits.

Energy consumption often decreases as systems operate more optimally. Production throughput increases as equipment runs more reliably. Quality metrics improve as process variations are detected and corrected immediately.

Efficiency Gains Beyond the Obvious ⚙️

While performance improvements are compelling, the efficiency benefits of edge-based fault detection extend into less obvious but equally valuable areas.

Bandwidth and Cloud Cost Optimization

Processing data locally on edge devices dramatically reduces the volume of information transmitted to cloud systems. Instead of streaming raw sensor data continuously, edge devices send only processed insights, alerts, and aggregated metrics.

This reduction can be substantial—organizations report 70-90% decreases in data transmission volumes. The corresponding reduction in bandwidth costs and cloud storage expenses quickly accumulates, often justifying the edge infrastructure investment within months.

Energy Efficiency Improvements

Modern edge devices are designed for power efficiency, and local processing often consumes less energy than transmitting data to distant cloud servers. Additionally, the system optimizations enabled by real-time fault detection frequently reduce overall energy consumption in the monitored equipment.

Smart buildings using edge-based fault detection for HVAC systems report energy savings of 15-25%. Industrial facilities see similar gains as processes run more efficiently and equipment operates closer to optimal parameters.

Labor Productivity Enhancement

Maintenance teams become significantly more productive when equipped with real-time fault detection systems. Instead of performing routine inspections or responding to unexpected failures, technicians can focus on addressing actual issues identified by the system.

Diagnostic information provided by edge analytics reduces troubleshooting time. Technicians arrive at equipment locations knowing what’s wrong and what parts they need, eliminating multiple trips and guesswork. This precision transforms maintenance from reactive firefighting to proactive optimization.

Industry Applications Driving Innovation 🏭

Real-time fault detection on edge devices is making significant impacts across diverse industries, each with unique requirements and challenges.

Manufacturing and Industrial Automation

Manufacturing environments were among the earliest adopters of edge-based fault detection. Production lines equipped with intelligent sensors monitor everything from motor vibrations to product quality metrics, identifying issues before they cause production stoppages.

Automotive manufacturers use these systems to maintain robotic assembly lines, while food processing plants monitor equipment hygiene and operational safety. The common thread is reducing unplanned downtime while maintaining quality standards.

Energy and Utilities

Power generation facilities, oil and gas operations, and renewable energy installations rely on edge-based monitoring to maintain critical infrastructure. Wind turbines equipped with vibration and temperature sensors can detect bearing failures weeks before catastrophic damage occurs.

Smart grid systems use edge analytics to identify electrical anomalies, predict transformer failures, and optimize power distribution in real-time. These capabilities are essential for maintaining reliable energy delivery while integrating variable renewable sources.

Transportation and Automotive

Modern vehicles are essentially mobile edge computing platforms with hundreds of sensors monitoring engine performance, brake conditions, tire pressure, and countless other parameters. Real-time fault detection enables predictive maintenance alerts and enhances vehicle safety.

Fleet management systems leverage edge analytics to optimize maintenance schedules across hundreds or thousands of vehicles, reducing operational costs while improving reliability. Commercial aviation uses similar approaches to monitor aircraft systems continuously.

Healthcare and Medical Devices

Medical equipment requires exceptional reliability, making fault detection critical. Edge-based monitoring systems ensure that imaging devices, patient monitors, and life-support equipment function optimally, alerting technicians to potential issues before they affect patient care.

Wearable medical devices increasingly incorporate edge analytics to monitor patient vitals in real-time, detecting concerning patterns and alerting healthcare providers immediately when intervention is needed.

Overcoming Implementation Challenges 🛠️

While the benefits are substantial, successfully implementing real-time fault detection on edge devices requires addressing several technical and organizational challenges.

Hardware Constraints and Optimization

Edge devices typically have limited computational resources, memory, and power compared to cloud servers. Deploying sophisticated machine learning models within these constraints requires careful optimization.

Successful implementations use lightweight model architectures, efficient programming languages like C++ or Rust, and hardware acceleration when available. Model selection must balance accuracy with computational feasibility, sometimes requiring trade-offs.

Data Quality and Sensor Calibration

Fault detection accuracy depends entirely on quality sensor data. Sensors require regular calibration, and systems must account for sensor drift, environmental interference, and occasional sensor failures.

Robust implementations incorporate data validation checks, cross-sensor verification, and automated calibration routines. Redundant sensors for critical measurements provide reliability even when individual sensors fail.

Model Training and Updates

Machine learning models need training data representing both normal operation and various fault conditions. Collecting comprehensive training datasets can be challenging, particularly for rare failure modes.

Additionally, operational conditions change over time, requiring model updates. Edge systems must support over-the-air updates while maintaining operational continuity. Federated learning approaches enable model improvement using distributed edge data without centralizing sensitive information.

Security Considerations for Edge Deployments 🔒

Edge devices deployed in critical infrastructure become potential security targets. Implementing robust security measures is essential for protecting both the devices themselves and the systems they monitor.

Security best practices include encrypted communications, secure boot processes, regular firmware updates, and network segmentation. Authentication mechanisms prevent unauthorized access, while intrusion detection systems identify potential compromise attempts.

Physical security also matters—edge devices in accessible locations need tamper-resistant enclosures and mechanisms to detect physical interference. Security cannot be an afterthought but must be integrated into system design from the beginning.

Future Trends Shaping Edge-Based Fault Detection 🔮

The field continues evolving rapidly, with several emerging trends promising to enhance capabilities further.

Advanced AI at the Edge

Next-generation edge processors with dedicated AI accelerators will enable more sophisticated models running locally. Technologies like neural processing units (NPUs) and tensor processing units (TPUs) are becoming available in edge form factors, dramatically expanding analytical capabilities.

These advances will enable edge devices to run complex deep learning models that currently require cloud processing, further reducing latency and improving real-time responsiveness.

5G and Edge Computing Convergence

The rollout of 5G networks with ultra-low latency creates new possibilities for distributed edge architectures. Multi-access edge computing (MEC) enables processing at network edges, combining local device intelligence with nearby computational resources.

This hybrid approach offers the best of both worlds—the immediacy of on-device processing with access to greater computational power when needed for complex analyses.

Digital Twins and Simulation Integration

Digital twin technology—creating virtual replicas of physical assets—is increasingly integrated with edge-based fault detection. Real-time data from edge devices continuously updates digital twins, enabling sophisticated simulation and prediction capabilities.

This integration allows testing of “what-if” scenarios, optimization of operational parameters, and prediction of long-term equipment degradation with unprecedented accuracy.

Making the Business Case for Edge Implementation 💼

Convincing stakeholders to invest in edge-based fault detection requires demonstrating clear return on investment. The business case typically rests on several quantifiable benefits.

Calculate potential savings from reduced downtime by multiplying average downtime hours by hourly operational costs, then applying expected reduction percentages. Add maintenance cost savings from transitioning to predictive rather than reactive approaches. Include energy savings, extended equipment lifespan, and improved product quality.

Most organizations find payback periods ranging from 6 to 24 months, depending on industry, equipment criticality, and implementation scale. The ongoing operational benefits continue accumulating year after year, making the long-term value proposition compelling.

Getting Started With Edge-Based Fault Detection 🚀

Organizations ready to implement these systems should approach deployment strategically, starting with pilot projects on high-value equipment before expanding broadly.

Begin by identifying critical assets where downtime is most costly or where safety concerns are paramount. Assess existing sensor infrastructure and determine what additional instrumentation is needed. Evaluate edge computing platforms based on computational requirements, environmental conditions, and integration capabilities.

Partner with vendors and consultants experienced in your industry’s specific challenges. Successful implementations require expertise spanning industrial processes, data science, edge computing, and cybersecurity—rarely found entirely in-house.

Establish clear success metrics before deployment, tracking downtime reduction, maintenance efficiency improvements, and cost savings. These measurements validate the investment and guide ongoing optimization efforts.

Transforming Operations Through Intelligent Edge Systems 🌟

Real-time fault detection on edge devices represents a fundamental shift in how organizations monitor, maintain, and optimize critical equipment. The combination of immediate insights, reduced latency, improved efficiency, and enhanced reliability creates compelling advantages across industries.

As edge computing technology continues advancing and becoming more accessible, organizations of all sizes can leverage these capabilities. The competitive advantages—reduced costs, improved reliability, enhanced safety, and operational excellence—make adoption not just beneficial but increasingly necessary for staying ahead in today’s fast-paced industrial landscape.

The question is no longer whether to implement edge-based fault detection, but how quickly organizations can deploy these transformative systems to boost performance, efficiency, and competitive positioning in their markets.

Toni Santos is a technical researcher and aerospace safety specialist focusing on the study of airspace protection systems, predictive hazard analysis, and the computational models embedded in flight safety protocols. Through an interdisciplinary and data-driven lens, Toni investigates how aviation technology has encoded precision, reliability, and safety into autonomous flight systems — across platforms, sensors, and critical operations. His work is grounded in a fascination with sensors not only as devices, but as carriers of critical intelligence. From collision-risk modeling algorithms to emergency descent systems and location precision mapping, Toni uncovers the analytical and diagnostic tools through which systems preserve their capacity to detect failure and ensure safe navigation. With a background in sensor diagnostics and aerospace system analysis, Toni blends fault detection with predictive modeling to reveal how sensors are used to shape accuracy, transmit real-time data, and encode navigational intelligence. As the creative mind behind zavrixon, Toni curates technical frameworks, predictive safety models, and diagnostic interpretations that advance the deep operational ties between sensors, navigation, and autonomous flight reliability. His work is a tribute to: The predictive accuracy of Collision-Risk Modeling Systems The critical protocols of Emergency Descent and Safety Response The navigational precision of Location Mapping Technologies The layered diagnostic logic of Sensor Fault Detection and Analysis Whether you're an aerospace engineer, safety analyst, or curious explorer of flight system intelligence, Toni invites you to explore the hidden architecture of navigation technology — one sensor, one algorithm, one safeguard at a time.