In today’s fast-paced business environment, gradual changes in systems, processes, and equipment can silently erode performance, leading to catastrophic failures that could have been prevented with early detection. 🎯

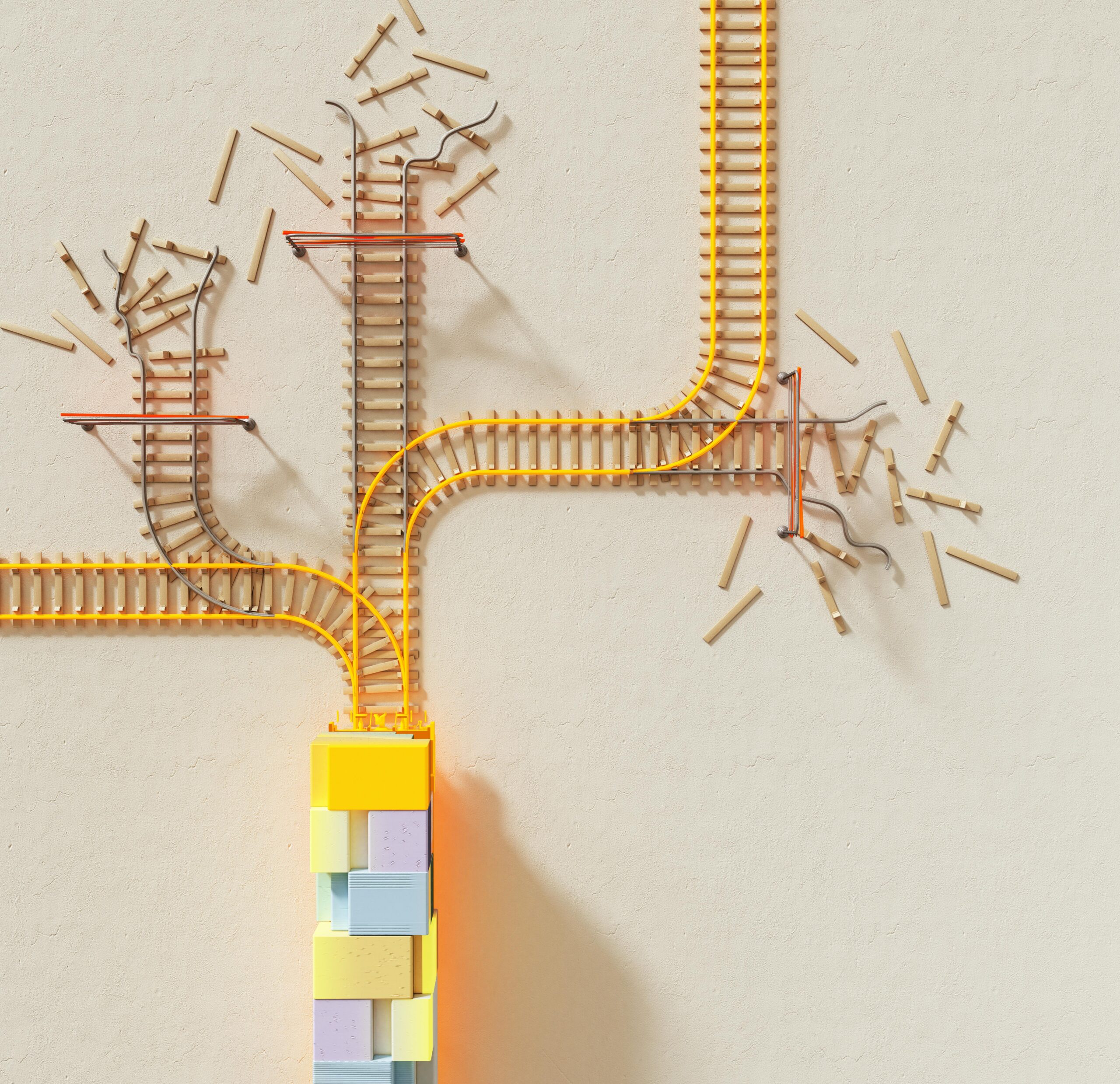

Organizations across industries face a common challenge: identifying subtle deteriorations before they cascade into expensive breakdowns, quality issues, or complete system failures. The concept of “slow drift” refers to these gradual deviations from optimal performance that occur over extended periods, often going unnoticed until significant damage has already been done.

Understanding and detecting slow drift early represents one of the most valuable capabilities any organization can develop. Unlike sudden failures that announce themselves dramatically, slow drift operates in stealth mode, quietly compromising efficiency, accuracy, and reliability. By the time traditional monitoring systems flag a problem, you’ve likely already experienced substantial losses in productivity, quality, or customer satisfaction.

🔍 Understanding the Nature of Slow Drift

Slow drift manifests differently across various domains, but its fundamental characteristic remains consistent: gradual, almost imperceptible changes that compound over time. In manufacturing environments, machine calibration might shift by microscopically small amounts each day. In software systems, response times might increase by milliseconds with each update or database entry. In business processes, standards might relax incrementally with each team member’s interpretation.

The insidious nature of slow drift lies in its ability to evade human perception. Our brains naturally adapt to gradual changes, making us remarkably poor at detecting drift through casual observation alone. What seemed unacceptably slow six months ago becomes the “new normal” today, until one day the system simply stops functioning entirely.

Consider a precision manufacturing operation where cutting tools gradually wear down. Each component produced might deviate from specifications by only 0.001 millimeters more than the previous one. Individual measurements might still fall within acceptable tolerances, but the trend points toward inevitable failure. By the time parts fail quality inspections, you’ve potentially produced thousands of defective units.

The Economic Impact of Undetected Drift

The financial consequences of failing to detect slow drift extend far beyond immediate repair costs. Organizations face multiple layers of economic damage:

- Accumulated waste: Gradual quality degradation produces increasing volumes of defective products or services before detection

- Emergency response costs: Sudden failures requiring immediate attention typically cost 3-5 times more than planned maintenance

- Reputation damage: Declining quality noticed by customers before internal systems can permanently harm brand value

- Regulatory exposure: Drift in compliance-critical systems can result in violations, fines, and legal liabilities

- Opportunity costs: Resources diverted to crisis management cannot be invested in growth initiatives

Research indicates that organizations implementing robust drift detection systems typically reduce unplanned downtime by 40-60% and extend equipment lifespan by 20-30%. The return on investment for early detection capabilities often exceeds 300% within the first two years of implementation.

📊 Key Indicators That Demand Continuous Monitoring

Effective drift detection requires identifying which metrics genuinely signal meaningful changes versus normal variation. Not every fluctuation indicates problematic drift, and monitoring everything is neither practical nor useful. Strategic monitoring focuses on leading indicators that provide early warning of developing issues.

Performance Metrics That Matter

In operational environments, certain performance characteristics serve as reliable drift indicators. Processing speeds, cycle times, throughput rates, and resource consumption patterns all provide valuable signals when tracked properly. The key lies in establishing baseline performance under optimal conditions and monitoring deviations from these baselines rather than simply tracking absolute values.

Temperature profiles offer particularly valuable insights across diverse applications. Electrical systems, mechanical equipment, and even computational resources exhibit temperature patterns that shift predictably as components degrade or conditions change. A motor drawing slightly more current each month, reflected in elevated operating temperatures, signals bearing wear, lubrication degradation, or electrical resistance changes long before catastrophic failure occurs.

Quality and Precision Measurements

For processes where output quality matters, dimensional accuracy, material properties, chemical compositions, and performance specifications provide critical drift indicators. Statistical process control techniques excel at identifying trends within apparently normal variation, flagging situations where the process mean shifts or variability increases even while individual measurements remain within specification limits.

Modern measurement technology enables continuous quality monitoring at scales previously impossible. Automated inspection systems, inline sensors, and testing equipment generate data streams that, when properly analyzed, reveal drift patterns weeks or months before human inspectors would notice problems.

🛠️ Implementing Effective Early Detection Systems

Building capabilities to detect slow drift early requires thoughtful system design that balances sensitivity against false alarms. The most sophisticated monitoring system becomes useless if it generates so many alerts that operators learn to ignore them. Effective implementation follows several key principles.

Establishing Meaningful Baselines

Accurate drift detection begins with understanding normal behavior. Comprehensive baseline establishment involves capturing performance under various operating conditions, seasonal variations, and load scenarios. A baseline derived from limited data or unrepresentative conditions will generate either excessive false positives or fail to detect genuine drift.

Baseline establishment should span sufficient time to capture natural variation while excluding known anomalies. For most systems, 30-90 days of stable operation provides adequate baseline data, though highly seasonal processes might require full annual cycles. The baseline itself should be dynamic, updated periodically to reflect genuine improvements or intentional changes while remaining stable enough to detect unintended drift.

Selecting Appropriate Detection Methods

Different drift patterns require different detection approaches. Statistical process control charts excel for detecting gradual mean shifts and variance changes. Time series analysis techniques identify seasonal patterns and trend components. Machine learning algorithms can recognize complex multivariate drift patterns that simple statistical methods miss.

The sophistication of detection methods should match the criticality and complexity of what you’re monitoring. Simple control charts might suffice for straightforward single-variable processes, while complex systems with interdependent variables benefit from advanced analytics. The goal is not to implement the most advanced technology but rather the most appropriate technology for your specific needs.

⚙️ Technology Enablers for Drift Detection

Modern technology has dramatically reduced both the cost and complexity of implementing comprehensive drift detection systems. Sensors, data acquisition systems, analytics platforms, and visualization tools have become increasingly accessible to organizations of all sizes.

IoT Sensors and Data Collection

The proliferation of low-cost Internet of Things sensors enables continuous monitoring of virtually any measurable parameter. Temperature, vibration, pressure, flow, position, chemical composition, acoustic signatures, and countless other characteristics can now be monitored continuously at price points that make widespread deployment economically feasible.

Wireless sensor networks eliminate much of the installation complexity and cost that previously limited monitoring scope. Battery-powered sensors with multi-year lifespans can be deployed in locations where wired sensors would be impractical. Edge computing capabilities built into modern sensors enable preliminary data processing and analysis at the point of collection, reducing bandwidth requirements and enabling faster response times.

Cloud-Based Analytics Platforms

Cloud computing has democratized access to sophisticated analytics capabilities. Organizations no longer need to invest in expensive on-premises infrastructure or maintain specialized expertise to implement advanced drift detection. Cloud-based platforms offer scalable processing power, pre-built analytics models, and intuitive interfaces that make sophisticated monitoring accessible to non-specialists.

These platforms typically provide automated alert generation, customizable dashboards, and integration capabilities with existing business systems. The subscription-based pricing models align costs with value received, making enterprise-grade capabilities accessible to small and medium-sized organizations.

🎯 Practical Strategies for Different Industries

While the fundamental principles of drift detection remain consistent across domains, effective implementation requires adapting approaches to industry-specific challenges and opportunities.

Manufacturing and Production Environments

Manufacturing operations benefit enormously from drift detection applied to equipment performance, product quality, and process efficiency. Predictive maintenance programs built on continuous monitoring can reduce unplanned downtime by more than half while extending equipment life significantly.

Integration with existing Manufacturing Execution Systems and Enterprise Resource Planning platforms enables drift detection insights to drive automated responses. When cutting tool wear reaches defined thresholds, the system automatically schedules replacement during the next planned maintenance window. When process parameters drift toward specification limits, operators receive guidance on corrective adjustments before defective products are produced.

Software and IT Systems

Digital systems experience drift through code complexity accumulation, database bloat, configuration creep, and resource utilization trends. Application performance monitoring tools track response times, error rates, resource consumption, and user experience metrics to identify degradation before users notice problems.

Continuous integration and deployment pipelines benefit from automated performance regression testing that compares each software version against established baselines. When response times increase or resource consumption grows beyond acceptable thresholds, the deployment can be automatically halted for investigation.

Service Delivery and Customer Experience

Service organizations face drift in process consistency, response times, quality standards, and customer satisfaction. Call center metrics like average handle time, first-call resolution rates, and customer satisfaction scores provide early indicators of developing issues.

Text analytics applied to customer communications can detect subtle shifts in sentiment or emerging complaint themes before they appear in formal feedback mechanisms. Drift in language patterns, topic distributions, or emotional tone often signals problems weeks or months before traditional customer satisfaction surveys reveal issues.

💡 Creating a Culture of Early Detection

Technology alone cannot prevent drift-related failures. Organizational culture plays an equally important role in whether early warning signals result in preventive action or are ignored until crisis forces response.

Empowering Frontline Recognition

Operators, technicians, and frontline staff often notice subtle changes in equipment behavior, process performance, or output quality before monitoring systems register measurable drift. Creating channels for these observations to be reported, investigated, and acted upon taps into valuable human pattern recognition capabilities that complement automated monitoring.

Recognition and reward systems that celebrate early problem identification encourage proactive reporting. When organizations punish messengers or ignore early warnings, staff quickly learn to remain silent until problems become undeniable. Conversely, cultures that value and act on early detection foster continuous improvement and genuine preventive maintenance.

Data-Driven Decision Making

Effective drift detection requires translating monitoring data into actionable decisions. This means establishing clear protocols for investigating alerts, determining root causes, and implementing corrective actions. Decision-making processes should balance the cost of false positives against the risk of missed detections, with clear escalation paths when initial responses prove inadequate.

Regular review of monitoring system effectiveness helps optimize alert thresholds, refine baselines, and improve detection algorithms. Systems that generate too many nuisance alarms require recalibration, while systems that missed detecting known drift incidents need sensitivity adjustments.

🚀 The Future of Drift Detection

Emerging technologies promise to make drift detection even more powerful and accessible. Artificial intelligence and machine learning continue advancing, enabling detection of increasingly subtle and complex drift patterns. Digital twin technology creates virtual replicas of physical systems, allowing simulation-based drift prediction and intervention testing before implementing changes in production environments.

Augmented reality interfaces will eventually provide technicians with real-time drift visualization overlaid on the equipment they’re inspecting. Blockchain-based verification systems will create tamper-proof records of baseline conditions and detected changes, supporting regulatory compliance and quality documentation requirements.

As these technologies mature and costs decline, comprehensive drift detection will become standard practice across industries, transforming from competitive advantage to basic operational requirement. Organizations that develop these capabilities early will benefit from years of operational excellence before competitors catch up.

🎓 Building Your Drift Detection Program

Starting a drift detection initiative doesn’t require massive investment or extensive delays. Begin by identifying your most critical processes, equipment, or systems where failure would be most costly. Implement basic monitoring for a few key parameters, establish baselines, and set conservative alert thresholds.

Gradually expand monitoring scope as you gain experience and demonstrate value. Use early successes to build organizational support for broader implementation. Invest in training staff to interpret monitoring data and respond appropriately to alerts. Document procedures, refine processes, and continuously improve system sensitivity and specificity.

The journey from reactive failure response to proactive drift detection transforms organizational performance, reduces costs, improves quality, and enhances competitiveness. Every day you delay implementation is another day of invisible deterioration accumulating throughout your operations. The time to start detecting slow drift is now, before small problems become costly failures.

Organizations that master early drift detection gain tremendous advantages: reduced downtime, extended asset life, improved quality, lower maintenance costs, and enhanced reputation. These benefits compound over time, creating sustainable competitive advantages that reactive competitors struggle to match. By staying ahead of the curve through vigilant monitoring and early intervention, you transform potential failures into opportunities for continuous improvement and operational excellence.

Toni Santos is a technical researcher and aerospace safety specialist focusing on the study of airspace protection systems, predictive hazard analysis, and the computational models embedded in flight safety protocols. Through an interdisciplinary and data-driven lens, Toni investigates how aviation technology has encoded precision, reliability, and safety into autonomous flight systems — across platforms, sensors, and critical operations. His work is grounded in a fascination with sensors not only as devices, but as carriers of critical intelligence. From collision-risk modeling algorithms to emergency descent systems and location precision mapping, Toni uncovers the analytical and diagnostic tools through which systems preserve their capacity to detect failure and ensure safe navigation. With a background in sensor diagnostics and aerospace system analysis, Toni blends fault detection with predictive modeling to reveal how sensors are used to shape accuracy, transmit real-time data, and encode navigational intelligence. As the creative mind behind zavrixon, Toni curates technical frameworks, predictive safety models, and diagnostic interpretations that advance the deep operational ties between sensors, navigation, and autonomous flight reliability. His work is a tribute to: The predictive accuracy of Collision-Risk Modeling Systems The critical protocols of Emergency Descent and Safety Response The navigational precision of Location Mapping Technologies The layered diagnostic logic of Sensor Fault Detection and Analysis Whether you're an aerospace engineer, safety analyst, or curious explorer of flight system intelligence, Toni invites you to explore the hidden architecture of navigation technology — one sensor, one algorithm, one safeguard at a time.