Fail-safe descent systems represent critical engineering solutions that ensure safety when primary systems fail, protecting lives and assets across industries worldwide.

🔐 Understanding the Core Philosophy of Fail-Safe Design

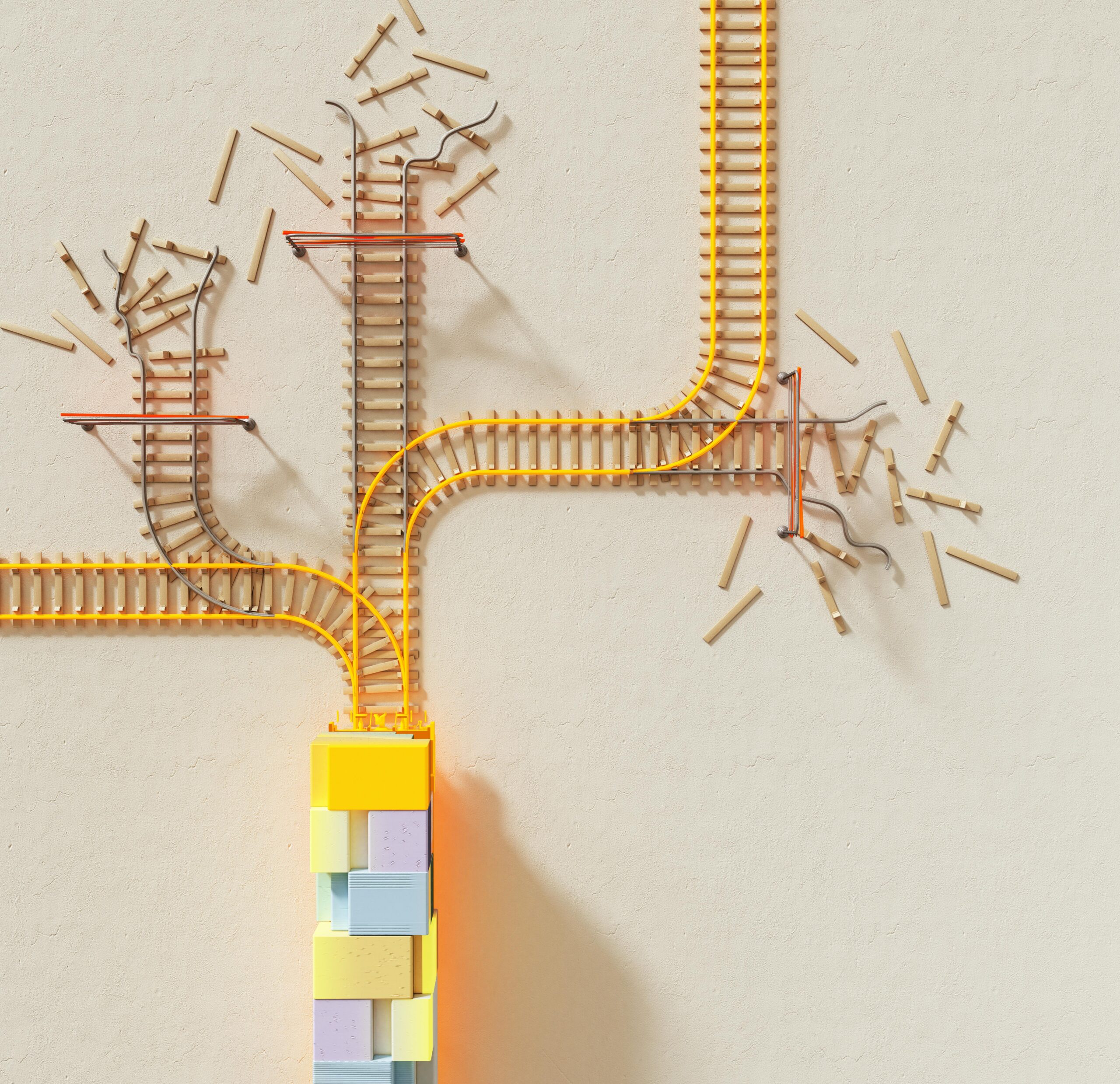

The concept of fail-safe descent systems stems from a fundamental principle in engineering: when something goes wrong, the system should default to a safe state rather than a catastrophic failure. This philosophy has saved countless lives in elevators, aircraft, industrial equipment, and construction sites. The core idea revolves around passive safety mechanisms that activate automatically without requiring human intervention or external power sources.

Modern fail-safe descent systems integrate redundant components, automatic engagement mechanisms, and energy-dissipating devices that work together seamlessly. These systems must function reliably under extreme conditions including power failures, mechanical breakdowns, and environmental challenges. The design process requires meticulous attention to detail, extensive testing protocols, and adherence to international safety standards that govern descent control mechanisms.

Engineers developing these systems face the challenge of balancing cost-effectiveness with absolute reliability. Every component must serve a purpose, and every failure mode must be anticipated and addressed. The stakes are particularly high in applications involving human transport, where a single malfunction could result in injuries or fatalities.

⚙️ Critical Components of Reliable Descent Systems

A comprehensive fail-safe descent system comprises several interconnected elements, each designed with redundancy and reliability at its core. The primary brake mechanism typically employs centrifugal governors or velocity-sensitive devices that engage automatically when descent speed exceeds predetermined thresholds. These components must be manufactured to exacting tolerances and tested rigorously before deployment.

Secondary safety catches provide an additional layer of protection, acting as mechanical backstops that physically prevent uncontrolled descent. These devices often utilize wedge-shaped grips or ratcheting mechanisms that lock onto guide rails or structural elements. The beauty of well-designed secondary systems lies in their simplicity—fewer moving parts means fewer potential failure points.

Energy absorption systems play a crucial role in controlling descent rates during emergency situations. These may include fluid dampers, friction brakes, or specially designed spring assemblies that gradually dissipate kinetic energy. The selection of energy absorption technology depends on the specific application, load capacity requirements, and environmental operating conditions.

Material Selection and Durability Considerations

The materials used in fail-safe descent systems must withstand years of potential inactivity followed by immediate, flawless activation during emergencies. Corrosion-resistant alloys, high-strength steel cables, and specialized polymers are carefully selected based on their mechanical properties, environmental resistance, and fatigue characteristics. Material degradation over time represents one of the most significant challenges in maintaining long-term system reliability.

Regular inspection protocols must account for material aging, stress corrosion cracking, and environmental exposure. Components exposed to weather, temperature extremes, or corrosive atmospheres require more frequent evaluation and potentially shorter replacement intervals. The lifecycle management of materials becomes an integral part of the overall system safety strategy.

📊 Design Principles That Define Excellence

Successful fail-safe descent systems adhere to established design principles that have evolved through decades of engineering experience and incident analysis. The principle of redundancy ensures that multiple independent systems can perform the same safety function. If one system fails, others remain operational to maintain protection.

Diversity in design approaches provides additional security against common-cause failures. Rather than duplicating identical systems, engineers incorporate different technologies or activation mechanisms that won’t fail simultaneously due to the same root cause. This might mean combining mechanical, hydraulic, and electromagnetic safety devices in a single installation.

The principle of fail-safe defaults requires that any system failure must result in a safe condition. For descent systems, this typically means engaging brakes or arresting mechanisms rather than allowing uncontrolled movement. Power-off or de-energized states should always favor safety over operational convenience.

Testing Protocols and Validation Strategies

Comprehensive testing forms the foundation of reliable fail-safe systems. Initial design validation includes finite element analysis, stress testing, and failure mode effects analysis (FMEA) to identify potential weaknesses before physical prototypes are built. Computer simulations allow engineers to test scenarios that would be dangerous or impractical to reproduce with actual equipment.

Physical testing must replicate real-world conditions including extreme loads, environmental stresses, and repeated activation cycles. Destructive testing pushes components beyond their rated capacities to determine actual failure thresholds and safety margins. Non-destructive evaluation techniques such as ultrasonic inspection, radiography, and magnetic particle testing help identify internal defects without compromising component integrity.

Field testing under operational conditions provides the final validation before systems enter service. These tests often involve instrumented installations that monitor performance parameters during actual use, providing data that informs maintenance schedules and design improvements for future generations of equipment.

🏗️ Industry-Specific Applications and Requirements

Elevator systems represent perhaps the most widely recognized application of fail-safe descent technology. Modern elevator safety systems incorporate multiple redundant brakes, overspeed governors, and buffer systems that protect passengers even during catastrophic cable failures. The sophistication of these systems reflects more than a century of continuous refinement and regulatory evolution.

In the construction industry, fall protection systems for workers at height utilize controlled descent devices that allow gradual lowering in emergencies. These personal safety systems must be lightweight, compact, and intuitive to use while maintaining absolute reliability under the stress of an actual fall event. Regular inspection and recertification requirements ensure continued performance throughout the equipment’s service life.

Industrial hoisting equipment, including cranes and material lifts, employ fail-safe descent systems to protect both personnel and valuable cargo. The load capacities involved can be substantial, requiring robust mechanical systems capable of arresting and controlling multi-ton loads during emergency situations. Hydraulic and mechanical braking systems work in concert to provide smooth, controlled descent rather than abrupt stops that could cause secondary damage.

Aviation and Aerospace Considerations

Aircraft landing gear systems incorporate complex fail-safe descent mechanisms that ensure wheels can be deployed even during complete hydraulic system failures. Emergency extension systems often use gravity-assisted deployment combined with mechanical locking mechanisms to guarantee wheels reach the down-and-locked position. The certification requirements for these systems are among the most stringent in any industry.

Emergency escape systems for aircraft crew and passengers utilize descent devices designed for rapid but controlled egress from elevated positions. These systems must function reliably after years of storage, often in harsh environmental conditions, and perform flawlessly on first activation during high-stress emergency scenarios.

🔧 Maintenance Strategies for Long-Term Reliability

Preventive maintenance programs form the cornerstone of sustained fail-safe system performance. Regular inspection intervals must be established based on manufacturer recommendations, regulatory requirements, and operational experience. Documentation of all maintenance activities creates a historical record that helps identify trends and predict potential failures before they occur.

Lubrication of moving components prevents wear and corrosion while ensuring smooth activation when safety systems engage. The selection of appropriate lubricants must consider operating temperature ranges, compatibility with component materials, and longevity between service intervals. Over-lubrication can be as problematic as insufficient lubrication, potentially causing contamination or interfering with brake function.

Functional testing during maintenance verifies that safety systems activate properly and perform within specified parameters. These tests must be carefully planned and executed to confirm functionality without creating hazards for maintenance personnel or damaging equipment. Simulated emergency conditions allow verification of system response without triggering actual emergency situations.

Predictive Maintenance Technologies

Advanced monitoring systems increasingly enable predictive maintenance approaches that identify developing problems before they compromise safety. Sensors monitor vibration signatures, temperature profiles, and wear indicators to detect abnormal conditions. Data analytics and machine learning algorithms can recognize patterns that precede component failures, triggering preemptive maintenance actions.

Wireless sensor networks facilitate real-time monitoring of distributed safety systems across large facilities or multiple installations. Centralized monitoring stations allow maintenance teams to track the health of numerous fail-safe systems simultaneously, prioritizing inspection and maintenance activities based on actual condition rather than predetermined schedules alone.

📋 Regulatory Framework and Compliance Standards

International standards organizations including ISO, ANSI, and ASME publish comprehensive guidelines for fail-safe descent system design, installation, and maintenance. These standards represent consensus among industry experts, manufacturers, and regulatory authorities regarding best practices and minimum safety requirements. Compliance with applicable standards is often legally mandated and forms the basis for liability protection.

Certification processes verify that manufactured systems meet published standards and perform as specified. Independent testing laboratories conduct evaluations that may include load testing, endurance cycling, environmental exposure, and failure mode verification. Certification marks provide assurance to end users and regulatory authorities that equipment meets recognized safety benchmarks.

Local building codes and occupational safety regulations impose additional requirements that may exceed international standards. Design engineers must navigate this complex regulatory landscape to ensure full compliance across all jurisdictions where equipment will be installed. Regular updates to codes and standards require ongoing attention to maintain compliance throughout a system’s operational life.

🚀 Emerging Technologies and Future Innovations

Smart materials that respond automatically to stress or environmental conditions offer promising applications in next-generation fail-safe systems. Shape memory alloys can trigger mechanical changes at specific temperatures or loads, providing passive activation without electronic controls. Magnetorheological fluids enable variable-rate energy absorption that adapts to descent speed and load conditions in real-time.

Integrated electronic monitoring systems provide comprehensive data about system status, usage patterns, and maintenance needs. These systems can communicate with building management platforms or central monitoring facilities, enabling proactive maintenance and immediate notification of anomalous conditions. The challenge lies in ensuring electronic enhancements don’t compromise the fundamental mechanical reliability that defines fail-safe performance.

Additive manufacturing technologies enable production of complex geometries and optimized component designs that would be impossible or prohibitively expensive using traditional manufacturing methods. Topology optimization algorithms can generate component designs that maximize strength while minimizing weight, improving both performance and cost-effectiveness. However, the long-term durability and certification of additively manufactured safety components remains an area of ongoing research and regulatory development.

💡 Lessons from Failure Analysis and Continuous Improvement

Systematic investigation of system failures, near-misses, and degraded performance provides invaluable insights for design improvement. Root cause analysis methodologies identify not just immediate failure mechanisms but underlying design, manufacturing, or maintenance issues that contributed to problems. This knowledge feeds directly into revised design standards and improved maintenance protocols.

Industry-wide incident reporting systems allow manufacturers and engineers to learn from failures across multiple installations and operating environments. Collaborative approaches to safety improvement benefit all stakeholders by raising the collective understanding of failure modes and effective mitigation strategies. Transparency in reporting and analysis ultimately leads to safer systems for everyone.

The continuous improvement cycle in fail-safe system design never truly ends. Each generation of equipment incorporates lessons learned from previous designs while adapting to new materials, technologies, and applications. The goal remains constant: ensuring that when primary systems fail, backup mechanisms provide reliable protection without exception.

🎯 Implementing Excellence in Your Organization

Organizations responsible for fail-safe descent systems must foster a culture where safety takes absolute precedence over convenience or cost savings. This begins with leadership commitment and extends through every level of the organization. Training programs ensure that everyone from design engineers to maintenance technicians understands their role in maintaining system integrity.

Investment in quality components and proper installation pays dividends through reduced maintenance costs and enhanced reliability over the system’s lifecycle. While initial costs may be higher for premium components, the total cost of ownership typically favors quality over economy. The potential costs of failure—both human and financial—dwarf any savings from compromising on system quality.

Documentation and knowledge management systems preserve institutional understanding of system design, maintenance history, and performance characteristics. As personnel change over time, comprehensive documentation ensures continuity of proper maintenance practices and informed decision-making regarding system modifications or replacements.

🌟 Building a Foundation for Sustained Safety

The principles of fail-safe descent system design extend beyond technical specifications to encompass organizational commitment, regulatory compliance, and continuous vigilance. Success in this domain requires balancing multiple competing demands while never compromising on the fundamental requirement: absolute reliability when it matters most. Engineers, maintenance professionals, and organizational leaders must work together to create systems that protect lives and property through decades of service.

As technology advances and applications become more demanding, the core principles remain unchanged. Redundancy, diversity, passive safety, and rigorous testing continue to define excellence in fail-safe design. The challenge for future generations lies in applying these timeless principles to emerging technologies and novel applications while maintaining the unwavering focus on safety that has characterized the best examples of descent system engineering.

Organizations that embrace these principles and commit to excellence in implementation, maintenance, and continuous improvement position themselves as industry leaders. More importantly, they fulfill the fundamental responsibility to protect the people and assets that depend on their systems performing flawlessly when called upon.

Toni Santos is a technical researcher and aerospace safety specialist focusing on the study of airspace protection systems, predictive hazard analysis, and the computational models embedded in flight safety protocols. Through an interdisciplinary and data-driven lens, Toni investigates how aviation technology has encoded precision, reliability, and safety into autonomous flight systems — across platforms, sensors, and critical operations. His work is grounded in a fascination with sensors not only as devices, but as carriers of critical intelligence. From collision-risk modeling algorithms to emergency descent systems and location precision mapping, Toni uncovers the analytical and diagnostic tools through which systems preserve their capacity to detect failure and ensure safe navigation. With a background in sensor diagnostics and aerospace system analysis, Toni blends fault detection with predictive modeling to reveal how sensors are used to shape accuracy, transmit real-time data, and encode navigational intelligence. As the creative mind behind zavrixon, Toni curates technical frameworks, predictive safety models, and diagnostic interpretations that advance the deep operational ties between sensors, navigation, and autonomous flight reliability. His work is a tribute to: The predictive accuracy of Collision-Risk Modeling Systems The critical protocols of Emergency Descent and Safety Response The navigational precision of Location Mapping Technologies The layered diagnostic logic of Sensor Fault Detection and Analysis Whether you're an aerospace engineer, safety analyst, or curious explorer of flight system intelligence, Toni invites you to explore the hidden architecture of navigation technology — one sensor, one algorithm, one safeguard at a time.