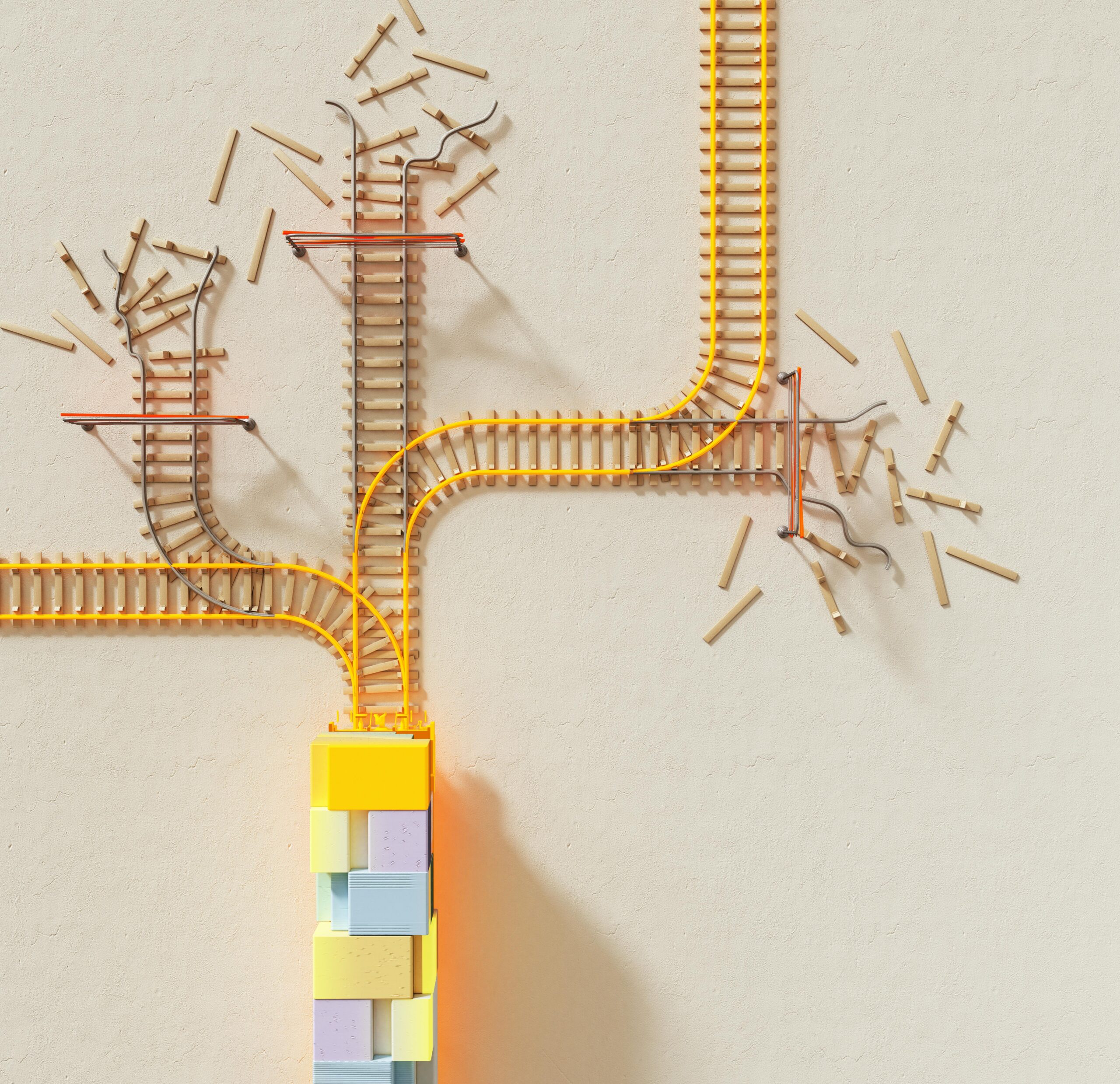

Industrial robotics revolutionizes manufacturing, but without proper risk modeling, these powerful machines can pose significant hazards to workers, operations, and profitability.

🤖 Understanding the Critical Importance of Risk Modeling in Robotics

The integration of industrial robots into manufacturing environments has transformed production capabilities across industries. From automotive assembly lines to pharmaceutical packaging facilities, robots perform tasks with precision and efficiency that human workers cannot match. However, this technological advancement comes with inherent risks that demand systematic assessment and management.

Risk modeling for industrial robotics isn’t simply about compliance with safety regulations—it’s about creating a comprehensive framework that protects human workers, preserves equipment investments, and maintains operational continuity. When organizations implement robust risk modeling practices, they reduce workplace injuries by up to 70%, according to recent industry studies.

The financial implications of inadequate risk assessment extend far beyond immediate safety concerns. Unplanned downtime from robotic accidents costs manufacturers an average of $260,000 per hour in lost productivity. Moreover, workplace injuries involving robotics can result in litigation costs exceeding millions of dollars, not to mention the immeasurable human cost.

The Foundation: Core Components of Effective Risk Assessment

Building a reliable risk model for industrial robotics requires understanding several foundational elements. These components work together to create a comprehensive safety ecosystem that addresses both predictable hazards and unexpected scenarios.

Hazard Identification and Classification

The first step in any risk modeling process involves identifying potential hazards associated with robotic systems. These hazards typically fall into several categories:

- Mechanical hazards including crushing, shearing, and impact injuries

- Electrical hazards from power systems and control circuits

- Thermal hazards from welding operations or heated components

- Noise and vibration exposure exceeding safe thresholds

- Ergonomic risks from maintenance and programming tasks

- System malfunction or unexpected robot behavior

- Human error during operation or programming

Each identified hazard must be documented with specific details about where, when, and how it might occur. This documentation becomes the foundation for subsequent risk analysis and mitigation strategies.

Probability Assessment Methodologies

Determining how likely each identified hazard is to occur requires systematic evaluation. Risk modeling professionals typically use historical data, manufacturer specifications, and operational parameters to calculate probability scores. This quantitative approach transforms subjective safety concerns into measurable risk factors.

Advanced facilities now employ machine learning algorithms to analyze patterns in sensor data, maintenance logs, and incident reports. These systems can predict potential failures before they occur, enabling proactive intervention rather than reactive responses.

⚙️ ISO Standards and Regulatory Frameworks Shaping Robot Safety

International standards provide the blueprint for comprehensive risk modeling in industrial robotics. Understanding and implementing these frameworks ensures both legal compliance and best-practice safety measures.

ISO 10218: The Global Standard for Robot Safety

ISO 10218 establishes fundamental safety requirements for industrial robots and robotic systems. This two-part standard addresses both robot manufacturers (Part 1) and system integrators (Part 2), creating a complete safety lifecycle approach.

The standard emphasizes risk assessment as an iterative process that continues throughout the robot’s operational life. It requires documentation of safety functions, protective measures, and validation procedures that prove risk reduction measures actually work as intended.

ISO/TS 15066: Collaborative Robot Operations

As collaborative robots (cobots) become increasingly common in manufacturing environments, ISO/TS 15066 provides specific guidance for human-robot collaboration. This technical specification defines permissible contact forces and pressures between robots and humans, establishing biomechanical limits that prevent injury.

Risk models for collaborative applications must account for dynamic interactions where humans and robots share workspace without traditional guarding. This requires sophisticated sensor systems, force-limiting technology, and carefully validated safety functions.

Building Your Risk Model: A Systematic Approach

Creating an effective risk model requires following a structured methodology that ensures no critical factors are overlooked. This systematic approach transforms complex safety challenges into manageable, actionable steps.

Step One: Define System Boundaries and Operating Conditions

Before assessing risks, you must clearly define what’s included in your robotic system. This encompasses not just the robot itself, but also end-effectors, tooling, material handling equipment, safety devices, and the physical workspace. Understanding intended use, reasonably foreseeable misuse, and environmental conditions provides essential context for risk evaluation.

Step Two: Task Analysis and Process Mapping

Detailed documentation of every task the robot performs reveals potential hazard exposure points. Process mapping should include normal production operations, changeover procedures, maintenance activities, and error recovery scenarios. Each task phase represents a unique risk profile requiring individual assessment.

Step Three: Risk Estimation Using Validated Matrices

Combining probability and severity data creates a risk estimation that guides mitigation priorities. Most organizations use risk matrices that plot likelihood against consequence, typically resulting in risk categories like negligible, low, medium, high, and very high.

| Severity | Rare | Unlikely | Possible | Likely | Almost Certain |

|---|---|---|---|---|---|

| Catastrophic | High | High | Very High | Very High | Very High |

| Major | Medium | High | High | Very High | Very High |

| Moderate | Low | Medium | High | High | Very High |

| Minor | Low | Low | Medium | Medium | High |

| Negligible | Low | Low | Low | Medium | Medium |

Step Four: Implementing the Hierarchy of Controls

Risk reduction follows a prioritized hierarchy that emphasizes elimination and engineering controls over administrative measures and personal protective equipment. This approach ensures the most effective safety solutions are implemented first.

Elimination removes the hazard entirely—for example, redesigning a process so that human workers never need to enter the robot’s operating zone during production. When elimination isn’t feasible, substitution might reduce risk by using less hazardous processes or materials.

Engineering controls include physical safeguarding systems such as light curtains, safety-rated monitored stops, and collaborative operation modes with force limiting. These technical solutions provide reliable, continuous protection that doesn’t depend on human behavior.

🛡️ Advanced Technologies Enhancing Risk Management

Modern risk modeling increasingly incorporates cutting-edge technologies that provide unprecedented insights into robotic system safety. These innovations enable predictive rather than reactive safety management.

Sensor Fusion and Real-Time Monitoring

Integrating data from multiple sensor types creates a comprehensive picture of system status and potential hazards. Vision systems, force-torque sensors, proximity detectors, and environmental monitors work together to detect anomalies that might indicate emerging risks.

Real-time analytics platforms process this sensor data continuously, comparing actual performance against expected parameters. When deviations exceed predetermined thresholds, automated alerts notify safety personnel and can trigger protective stops before hazardous situations develop.

Digital Twin Technology for Risk Simulation

Digital twins—virtual replicas of physical robotic systems—enable risk assessment without exposing workers to actual hazards. Engineers can simulate countless scenarios, test safety system responses, and validate risk mitigation strategies in a completely safe digital environment.

This technology proves particularly valuable when modifying existing robotic cells or introducing new products. Risks can be identified and addressed virtually before implementing changes in the physical workspace, dramatically reducing the potential for unexpected hazards.

Artificial Intelligence in Predictive Safety Analytics

AI algorithms analyze historical operational data to identify patterns correlating with safety incidents or near-misses. Machine learning models continuously improve their predictive accuracy, eventually forecasting potential hazards days or weeks before they might manifest.

These systems can detect subtle changes in robot performance—variations in cycle time, motor current, or positioning accuracy—that human observers might miss but which indicate developing mechanical problems or programming errors.

Human Factors: The Often-Overlooked Risk Variable

Even the most sophisticated technical risk model remains incomplete without addressing human factors. Workers interact with robotic systems during programming, teaching, maintenance, troubleshooting, and emergency response, each interaction presenting unique risk considerations.

Training and Competency Requirements

Comprehensive training programs must address not only normal operations but also abnormal situations and emergency procedures. Workers need practical experience recognizing hazardous conditions and understanding how safety systems function and can be compromised.

Competency validation should go beyond simple written tests to include practical demonstrations of safe work practices. Regular refresher training ensures skills remain current as systems are modified or new technologies are introduced.

Fatigue, Complacency, and Production Pressure

Risk models must account for human factors that increase likelihood of errors or unsafe behaviors. Production pressure can tempt workers to bypass safety systems to meet deadlines. Familiarity with robotic systems sometimes breeds complacency, reducing vigilance around known hazards.

Organizational culture significantly influences whether workers feel empowered to raise safety concerns or refuse unsafe work. Risk modeling should include assessment of these cultural factors and their impact on actual safety performance versus documented procedures.

📊 Continuous Improvement Through Safety Performance Metrics

Effective risk modeling doesn’t end with initial implementation—it requires ongoing monitoring and refinement based on actual performance data. Establishing the right metrics enables objective evaluation of risk management effectiveness.

Leading Versus Lagging Indicators

Lagging indicators like injury rates and incident counts reveal safety performance after problems occur. While important, they don’t provide early warning of developing hazards. Leading indicators—near-miss reports, safety observation scores, preventive maintenance completion rates—offer predictive value that enables proactive intervention.

Balanced scorecards incorporating both leading and lagging metrics provide comprehensive visibility into safety management system performance. Trends in these metrics guide resource allocation and highlight areas requiring enhanced risk mitigation efforts.

Root Cause Analysis and Lessons Learned

When incidents or near-misses occur, thorough investigation reveals not just immediate causes but underlying system weaknesses. Root cause analysis techniques like the Five Whys or Fishbone diagrams trace problems back to their fundamental origins, enabling corrective actions that prevent recurrence.

Organizations with mature safety cultures treat incidents as learning opportunities, sharing lessons across facilities and incorporating findings into updated risk models. This knowledge transfer accelerates safety improvements throughout the enterprise.

💡 Emerging Risks in Next-Generation Robotic Systems

As robotic technology evolves, new risk categories emerge that traditional assessment methods might not fully address. Forward-thinking risk models must anticipate these developing hazards.

Autonomous Systems and Artificial Intelligence

Robots with AI-driven decision-making capabilities introduce uncertainty into risk assessment. When systems can modify their own behavior based on learning algorithms, ensuring they always operate within safe parameters becomes more complex. Risk models must address not just programmed behaviors but also emergent actions that might arise from adaptive algorithms.

Cybersecurity Vulnerabilities

Connected robotic systems face cyber threats that could compromise safety functions. Risk modeling must now consider scenarios where malicious actors remotely manipulate robot behavior or disable protective devices. Cybersecurity measures become essential safety controls, not just IT concerns.

Mobile and Collaborative Robot Fleets

When multiple autonomous mobile robots operate in shared spaces with humans and each other, interaction complexity multiplies exponentially. Traditional fixed-cell risk assessments don’t adequately address dynamic environments where hazard exposure points constantly shift. New modeling approaches must account for fleet coordination, traffic management, and emergent behaviors from multi-robot systems.

🎯 Strategic Implementation: Making Risk Modeling Practical and Sustainable

The most comprehensive risk model provides little value if it remains a theoretical document rather than a living tool that guides daily operations. Successful implementation requires practical strategies that embed risk management into organizational DNA.

Cross-Functional Safety Teams

Effective risk modeling requires input from diverse perspectives—operations, maintenance, engineering, safety professionals, and frontline workers. Cross-functional teams bring comprehensive knowledge of actual working conditions, technical capabilities, and practical constraints that individual specialists might miss.

These teams should meet regularly to review safety performance data, discuss near-misses, evaluate proposed changes, and update risk assessments as conditions evolve. Representation from all stakeholder groups ensures risk models reflect real-world complexities.

Documentation and Knowledge Management

Risk assessments, mitigation strategies, and safety validation documentation must be organized, accessible, and maintained current. Digital safety management systems enable version control, change tracking, and easy retrieval of critical information during audits or incident investigations.

Knowledge management extends beyond documentation to include visual aids, training materials, and decision support tools that help workers apply risk management principles during daily tasks. Making safety information readily available at points of use increases the likelihood it will actually influence behavior.

Transforming Safety Culture Through Risk Awareness

The ultimate goal of risk modeling extends beyond regulatory compliance to creating a workplace culture where safety is genuinely valued and practiced. When workers understand the logic behind safety measures and see leadership commitment to risk management, participation and engagement naturally follow.

Transparent communication about identified risks and mitigation strategies builds trust and demonstrates that safety concerns are taken seriously. Involving workers in risk assessment processes taps into their practical knowledge while increasing buy-in for resulting safety measures.

Recognition programs that celebrate proactive safety behaviors—reporting near-misses, suggesting improvements, mentoring colleagues—reinforce desired culture. When safety excellence becomes a point of pride rather than a compliance burden, risk management transforms from a program into an identity.

The journey toward maximizing safety through comprehensive risk modeling requires sustained commitment, but the rewards—protected workers, operational reliability, and organizational resilience—justify the investment. As industrial robotics continues advancing, organizations that master risk modeling will lead their industries in both innovation and safety performance. 🚀

Toni Santos is a technical researcher and aerospace safety specialist focusing on the study of airspace protection systems, predictive hazard analysis, and the computational models embedded in flight safety protocols. Through an interdisciplinary and data-driven lens, Toni investigates how aviation technology has encoded precision, reliability, and safety into autonomous flight systems — across platforms, sensors, and critical operations. His work is grounded in a fascination with sensors not only as devices, but as carriers of critical intelligence. From collision-risk modeling algorithms to emergency descent systems and location precision mapping, Toni uncovers the analytical and diagnostic tools through which systems preserve their capacity to detect failure and ensure safe navigation. With a background in sensor diagnostics and aerospace system analysis, Toni blends fault detection with predictive modeling to reveal how sensors are used to shape accuracy, transmit real-time data, and encode navigational intelligence. As the creative mind behind zavrixon, Toni curates technical frameworks, predictive safety models, and diagnostic interpretations that advance the deep operational ties between sensors, navigation, and autonomous flight reliability. His work is a tribute to: The predictive accuracy of Collision-Risk Modeling Systems The critical protocols of Emergency Descent and Safety Response The navigational precision of Location Mapping Technologies The layered diagnostic logic of Sensor Fault Detection and Analysis Whether you're an aerospace engineer, safety analyst, or curious explorer of flight system intelligence, Toni invites you to explore the hidden architecture of navigation technology — one sensor, one algorithm, one safeguard at a time.