Multi-sensor networks have become indispensable tools in modern industrial operations, transforming how organizations detect, diagnose, and prevent system failures across critical infrastructure.

🔍 Understanding the Foundation of Multi-Sensor Networks

The evolution of fault detection systems has been remarkable over the past decade. Traditional single-point monitoring solutions have given way to sophisticated multi-sensor networks that provide comprehensive visibility into complex operational environments. These networks combine multiple sensor types—temperature, vibration, pressure, acoustic, and chemical sensors—to create a holistic monitoring ecosystem that captures every nuance of system performance.

Multi-sensor networks operate on a fundamental principle: redundancy and diversity enhance reliability. When a single sensor might miss critical indicators or produce false positives, a network of complementary sensors cross-validates data, reducing uncertainty and improving detection accuracy. This approach has proven particularly valuable in industries where downtime costs millions per hour and safety cannot be compromised.

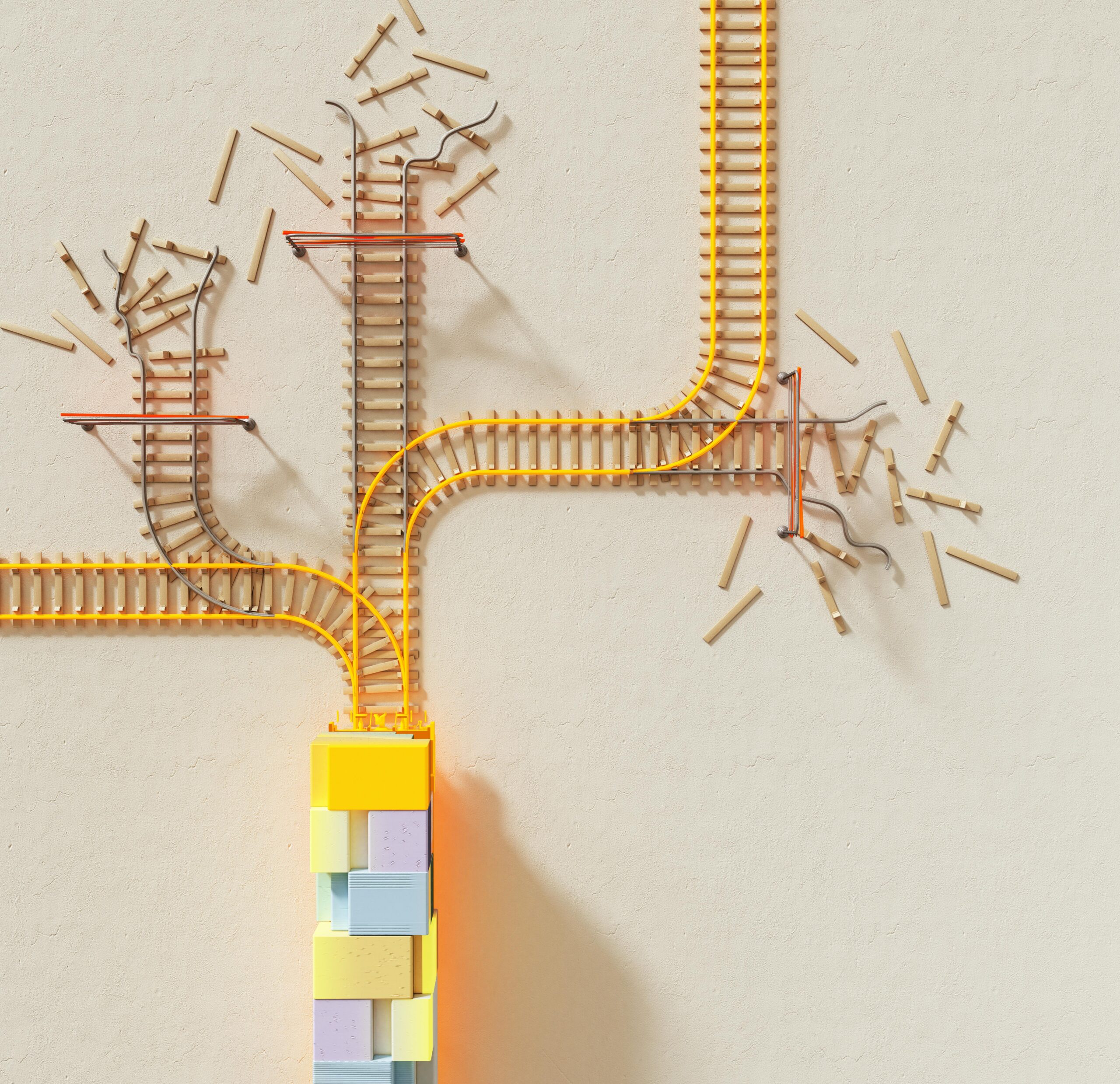

The architecture of these networks typically follows a hierarchical structure. Edge sensors collect raw data, local processing nodes perform initial analysis, and centralized systems aggregate information for comprehensive fault detection. This distributed intelligence allows for both real-time local responses and broader pattern recognition that reveals systemic issues.

🎯 The Critical Components of Effective Sensor Integration

Building a successful multi-sensor network requires careful consideration of several technical and strategic elements. Sensor selection stands as the foundation of any deployment. Each sensor type brings unique capabilities and limitations, and understanding these characteristics determines the network’s overall effectiveness.

Temperature sensors provide thermal profiles that reveal overheating, cooling system failures, and friction-related issues. Vibration sensors detect mechanical imbalances, bearing wear, and structural degradation long before visible symptoms appear. Pressure sensors monitor fluid systems, identifying leaks, blockages, and pump failures. Acoustic sensors pick up ultrasonic frequencies that indicate electrical arcing, gas leaks, and mechanical stress.

Synchronization and Data Fusion Strategies

Time synchronization across sensor networks presents both technical challenges and opportunities. When sensors operate independently without coordinated timing, correlating events becomes difficult or impossible. Advanced networks implement precision time protocols that ensure all sensors timestamp their readings with microsecond accuracy, enabling sophisticated event correlation and causality analysis.

Data fusion algorithms represent the intelligence layer that transforms raw sensor streams into actionable insights. These algorithms employ various techniques ranging from simple threshold-based rules to advanced machine learning models. Bayesian networks, neural networks, and support vector machines have all demonstrated success in different application contexts.

💡 Fault Detection Methodologies That Drive Success

The methodology employed for fault detection fundamentally determines system performance. Model-based approaches use mathematical representations of normal system behavior, flagging deviations as potential faults. These methods excel when physical models accurately represent system dynamics but struggle with complex, nonlinear systems where modeling proves challenging.

Data-driven approaches have gained prominence with the rise of machine learning and artificial intelligence. These methods learn normal operational patterns from historical data, identifying anomalies without requiring explicit physical models. Deep learning architectures, particularly convolutional and recurrent neural networks, have achieved remarkable success in extracting relevant features from raw sensor data.

Hybrid Approaches: Combining the Best of Both Worlds

Forward-thinking organizations increasingly adopt hybrid methodologies that combine model-based and data-driven techniques. These approaches leverage physical understanding where available while using machine learning to handle complex interactions that resist analytical modeling. The synergy between domain knowledge and data-driven discovery often produces superior results compared to either approach alone.

Rule-based expert systems remain valuable, particularly in well-understood domains with established failure modes. These systems encode decades of operational experience into decision trees and if-then rules that rapidly diagnose common faults. When integrated with machine learning components, they provide both interpretability and adaptability.

⚙️ Implementation Challenges and Practical Solutions

Deploying multi-sensor networks in real-world environments introduces numerous challenges that theoretical designs often overlook. Environmental conditions affect sensor performance in ways that laboratory testing cannot fully predict. Temperature extremes, humidity, vibration, electromagnetic interference, and physical contamination all impact measurement reliability.

Sensor calibration and drift management require ongoing attention. Even high-quality sensors experience gradual performance degradation over time. Systematic calibration protocols, coupled with automated drift detection algorithms, help maintain measurement accuracy. Some advanced networks implement self-calibrating sensors that automatically adjust based on known reference conditions or peer sensor comparisons.

Communication Infrastructure and Network Reliability

The communication backbone connecting sensors to processing systems represents a critical vulnerability. Wired networks offer reliability and security but impose installation costs and flexibility constraints. Wireless networks provide deployment ease and scalability but introduce concerns about bandwidth, latency, security, and power management.

Industrial Internet of Things (IIoT) protocols have matured significantly, offering robust solutions for sensor connectivity. Standards like OPC UA, MQTT, and CoAP provide interoperability across diverse sensor types and manufacturers. Edge computing architectures reduce bandwidth requirements by processing data locally, transmitting only relevant information or detected anomalies to central systems.

📊 Data Management and Analysis at Scale

Multi-sensor networks generate enormous data volumes that challenge traditional data management approaches. A single facility might deploy thousands of sensors, each sampling multiple times per second, producing terabytes of data daily. Effective data management strategies must balance completeness against practical storage and processing constraints.

Intelligent data reduction techniques preserve critical information while eliminating redundancy. Compression algorithms tailored for sensor data maintain fidelity while reducing storage requirements by orders of magnitude. Event-triggered recording captures full-resolution data only when anomalies occur, while routine operation generates lower-resolution summaries.

Real-Time Processing Versus Batch Analysis

The temporal requirements of fault detection vary significantly across applications. Emergency shutdown systems demand millisecond response times, requiring edge processing with minimal latency. Predictive maintenance applications tolerate longer processing windows, allowing more sophisticated analysis using centralized computing resources.

Stream processing frameworks enable real-time analytics on continuous data flows. Technologies like Apache Kafka, Apache Flink, and Apache Storm provide the infrastructure for processing millions of sensor readings per second, detecting patterns and anomalies as events unfold. These platforms support complex event processing that correlates information across multiple sensors and time windows.

🚀 Advanced Techniques Pushing the Boundaries

The frontier of multi-sensor fault detection continues advancing rapidly. Transfer learning techniques allow models trained on one system to adapt quickly to similar systems with minimal new training data. This capability dramatically reduces the time and cost of deploying fault detection systems across multiple facilities or equipment types.

Federated learning addresses privacy and bandwidth concerns in distributed sensor networks. Instead of transmitting raw data to central locations, local models train on local data and share only model updates. This approach enables collaborative learning across multiple sites while maintaining data sovereignty and reducing communication overhead.

Digital Twins and Virtual Sensing

Digital twin technology creates virtual replicas of physical systems that evolve in parallel with their real-world counterparts. These models integrate sensor data with physics-based simulations, providing estimates of unmeasured variables and enabling what-if analysis. Virtual sensors extrapolate information about inaccessible locations or parameters too expensive to measure directly.

Augmented reality interfaces are transforming how maintenance personnel interact with sensor networks. Technicians equipped with AR headsets see real-time sensor overlays on physical equipment, highlighting areas of concern and providing diagnostic guidance. This fusion of physical and digital information accelerates troubleshooting and improves maintenance quality.

🏭 Industry-Specific Applications and Success Stories

Manufacturing environments benefit enormously from multi-sensor fault detection. Production lines equipped with comprehensive sensor networks detect quality issues in real-time, preventing defective products from reaching customers. Predictive maintenance systems monitor critical equipment, scheduling interventions before failures occur and eliminating costly unplanned downtime.

Energy sector applications span generation, transmission, and distribution infrastructure. Power plants employ sensor networks monitoring turbines, boilers, and generators, detecting efficiency degradation and component wear. Smart grids use distributed sensors to monitor transmission lines, transformers, and substations, identifying faults and optimizing power flow.

Transportation and Aerospace Monitoring

Aircraft health monitoring systems represent some of the most sophisticated multi-sensor networks deployed today. Modern aircraft carry thousands of sensors monitoring engines, hydraulics, electrical systems, and structural integrity. Ground-based analytics systems process flight data, detecting emerging issues and optimizing maintenance schedules.

Railway systems increasingly rely on sensor networks for safety and reliability. Trackside sensors monitor wheel bearings, detecting overheating that precedes failures. Vibration sensors on tracks identify structural issues requiring maintenance. Integrated systems correlate information across the entire rail network, optimizing traffic flow while maintaining safety standards.

🔐 Security Considerations in Connected Sensor Ecosystems

As sensor networks become increasingly connected and internet-accessible, cybersecurity emerges as a paramount concern. Compromised sensors could feed false data into fault detection systems, causing inappropriate actions or masking real failures. Defense-in-depth strategies implement security at multiple layers, from individual sensors through communication channels to central processing systems.

Authentication and encryption protocols protect against unauthorized access and data tampering. Role-based access control ensures that users and systems access only the information necessary for their functions. Intrusion detection systems monitor network traffic for suspicious patterns that might indicate cyberattacks.

📈 Return on Investment and Business Value

Quantifying the business value of multi-sensor fault detection systems requires comprehensive analysis beyond initial implementation costs. Direct benefits include reduced downtime, extended equipment life, lower maintenance costs, and improved product quality. Indirect benefits encompass enhanced safety, regulatory compliance, and organizational knowledge preservation.

Calculating return on investment involves comparing total cost of ownership against avoided losses and efficiency gains. Organizations typically achieve payback periods ranging from several months to a few years, depending on application criticality and failure consequences. High-value assets in continuous production environments often justify sophisticated monitoring investments through preventing even a single catastrophic failure.

🌟 Building Organizational Capability for Long-Term Success

Technology alone does not guarantee fault detection success. Organizations must develop complementary capabilities in data science, domain expertise, and change management. Cross-functional teams combining operational experience with analytical skills create the synergy necessary to extract maximum value from sensor networks.

Training programs ensure that personnel understand both the capabilities and limitations of fault detection systems. Operators learn to interpret alerts correctly, distinguishing genuine issues from false positives. Maintenance teams understand how sensor insights inform repair and replacement decisions. Management appreciates the strategic value of predictive intelligence in operational planning.

Continuous improvement processes systematically refine fault detection performance over time. Regular reviews analyze detection accuracy, false alarm rates, and missed detections. Lessons learned from each incident feed back into model updates and operational procedures. This iterative refinement transforms initial systems into increasingly reliable and valuable assets.

🔮 The Future Landscape of Multi-Sensor Fault Detection

Emerging technologies promise to further revolutionize multi-sensor fault detection capabilities. Quantum sensors offer unprecedented sensitivity for detecting minute physical changes. Nanoscale sensors enable monitoring in previously inaccessible locations. Biodegradable sensors provide temporary monitoring without environmental impact or removal requirements.

Artificial intelligence continues advancing, with explainable AI addressing the black-box concerns that have limited adoption in safety-critical applications. Autonomous systems that not only detect faults but also execute appropriate responses are transitioning from research to reality. Self-healing systems automatically reconfigure to maintain operation despite component failures.

The convergence of multi-sensor networks with other digital technologies creates unprecedented opportunities. Blockchain provides tamper-proof records of sensor data and maintenance actions. 5G networks enable massive IoT deployments with ultra-reliable low-latency communication. Cloud and edge computing continue evolving, providing flexible infrastructure that scales with organizational needs.

Mastering multi-sensor networks represents a journey rather than a destination. Organizations that commit to developing these capabilities position themselves for competitive advantage in increasingly complex operational environments. The integration of diverse sensor technologies, sophisticated analytics, and human expertise creates resilient systems that detect faults early, prevent failures, and optimize performance. As technology continues advancing and business environments grow more challenging, the strategic importance of multi-sensor fault detection will only increase, making today’s investments the foundation for tomorrow’s operational excellence.

Toni Santos is a technical researcher and aerospace safety specialist focusing on the study of airspace protection systems, predictive hazard analysis, and the computational models embedded in flight safety protocols. Through an interdisciplinary and data-driven lens, Toni investigates how aviation technology has encoded precision, reliability, and safety into autonomous flight systems — across platforms, sensors, and critical operations. His work is grounded in a fascination with sensors not only as devices, but as carriers of critical intelligence. From collision-risk modeling algorithms to emergency descent systems and location precision mapping, Toni uncovers the analytical and diagnostic tools through which systems preserve their capacity to detect failure and ensure safe navigation. With a background in sensor diagnostics and aerospace system analysis, Toni blends fault detection with predictive modeling to reveal how sensors are used to shape accuracy, transmit real-time data, and encode navigational intelligence. As the creative mind behind zavrixon, Toni curates technical frameworks, predictive safety models, and diagnostic interpretations that advance the deep operational ties between sensors, navigation, and autonomous flight reliability. His work is a tribute to: The predictive accuracy of Collision-Risk Modeling Systems The critical protocols of Emergency Descent and Safety Response The navigational precision of Location Mapping Technologies The layered diagnostic logic of Sensor Fault Detection and Analysis Whether you're an aerospace engineer, safety analyst, or curious explorer of flight system intelligence, Toni invites you to explore the hidden architecture of navigation technology — one sensor, one algorithm, one safeguard at a time.