Physics-based models are revolutionizing fault detection by combining scientific principles with advanced computational methods, delivering unprecedented accuracy in identifying and resolving system failures across industries.

🔬 The Foundation of Physics-Based Fault Detection

In an era where industrial systems grow increasingly complex, traditional fault detection methods often fall short of identifying subtle anomalies before they escalate into catastrophic failures. Physics-based models emerge as a game-changing solution, leveraging fundamental laws of nature to predict, detect, and diagnose faults with remarkable precision.

Unlike purely data-driven approaches that rely exclusively on historical patterns, physics-based models incorporate first principles—the fundamental equations governing how systems behave. These models understand the “why” behind system behavior, not just the “what,” enabling them to detect anomalies even in unprecedented scenarios where data-driven models might fail.

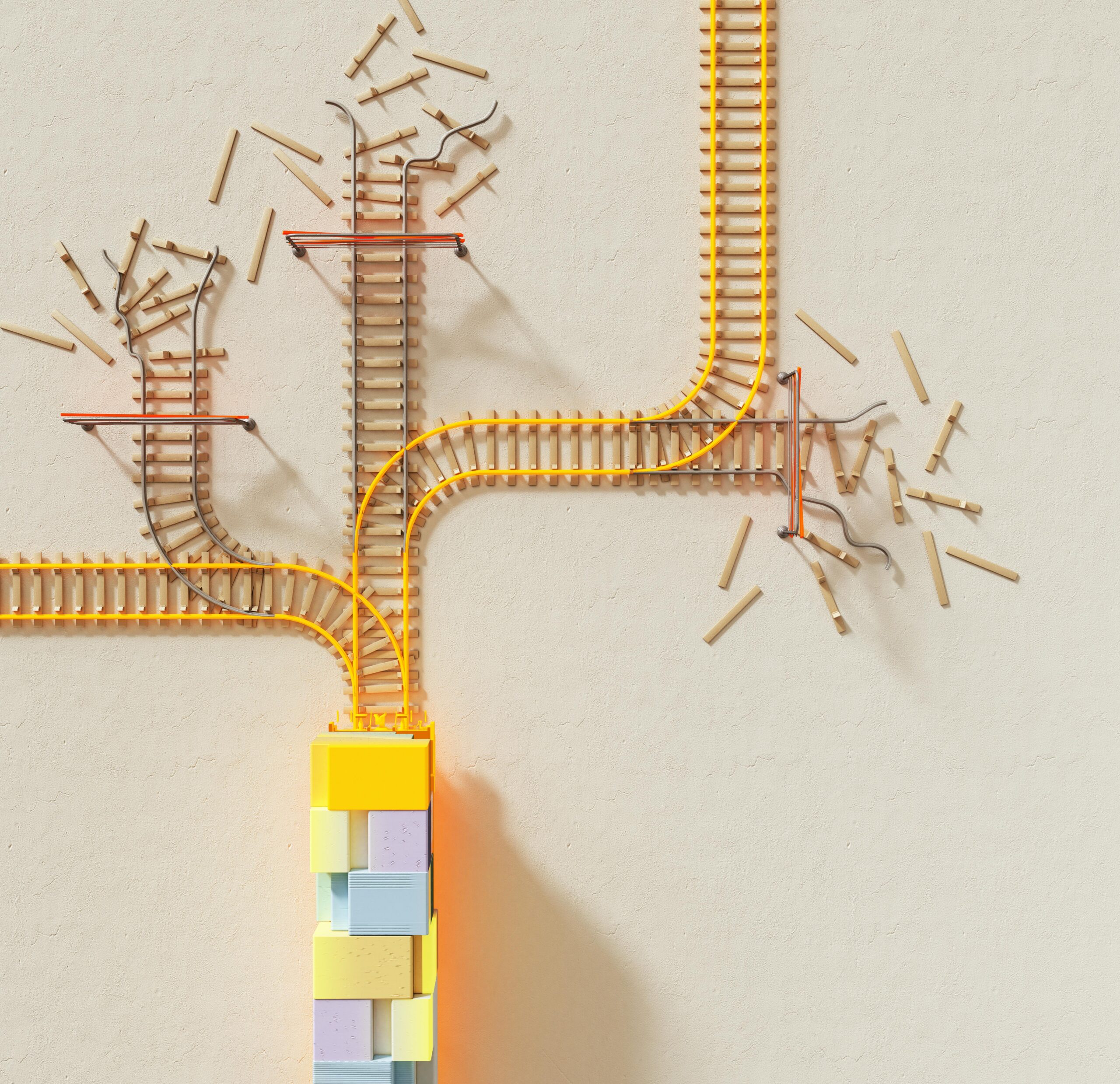

The integration of thermodynamics, fluid mechanics, structural mechanics, and electromagnetic theory into computational frameworks creates virtual replicas of physical systems. These digital twins simulate real-world behavior under various conditions, providing engineers with powerful tools to anticipate failures before they manifest in physical equipment.

⚙️ Why Traditional Methods Fall Short

Conventional fault detection techniques typically rely on statistical analysis, threshold monitoring, or machine learning algorithms trained on historical data. While these approaches have proven valuable, they share common limitations that physics-based models effectively address.

Statistical methods often generate false positives when systems operate under novel conditions outside their training data range. A production line running at unprecedented speeds or environmental conditions might trigger alarms unnecessarily, leading to costly downtime and reduced confidence in monitoring systems.

Data-driven machine learning models require extensive datasets capturing all possible fault scenarios—an impossibility for rare but critical failures. Physics-based models overcome this constraint by understanding fundamental system behavior, enabling accurate predictions even for fault types never previously observed.

Furthermore, black-box approaches offer limited insight into root causes. When an alarm triggers, operators need to understand why the system failed and how to prevent recurrence. Physics-based models provide transparent, explainable diagnostics grounded in scientific principles that engineers intuitively understand.

🌟 The Mechanics of Physics-Based Fault Detection

Physics-based fault detection systems operate through a sophisticated multi-stage process that combines modeling, simulation, and real-time comparison with actual system performance.

Building the Foundation: System Modeling

The process begins with creating accurate mathematical representations of physical systems. Engineers encode fundamental relationships—heat transfer equations for thermal systems, Navier-Stokes equations for fluid dynamics, or Maxwell’s equations for electromagnetic systems—into computational models.

These models capture component-level interactions and system-wide behaviors. For a rotating machine, the model might include bearing dynamics, shaft torsion, vibration modes, thermal expansion, and lubrication properties. Each element follows established physical laws, ensuring the model’s predictions align with reality.

Modern computational tools enable multiphysics simulations where thermal, mechanical, and electrical phenomena interact simultaneously. This holistic approach captures complex fault signatures that single-domain models might miss, such as how electrical imbalances create mechanical vibrations that accelerate thermal degradation.

Real-Time Comparison and Anomaly Detection

Once validated, physics-based models run parallel to actual systems, generating expected behavior predictions in real-time. Sensors continuously measure system parameters—temperatures, pressures, vibrations, currents—which are compared against model predictions.

Discrepancies between predicted and observed behavior indicate potential faults. The magnitude, pattern, and progression of these deviations provide diagnostic clues. A gradual divergence suggests degradation like wear or fouling, while sudden deviations indicate acute failures such as cracks or blockages.

Advanced implementations employ residual analysis techniques, examining the difference between predicted and measured values across multiple parameters simultaneously. This multidimensional approach dramatically improves detection sensitivity and reduces false alarms compared to single-parameter threshold monitoring.

🏭 Industry Applications Transforming Operations

Physics-based fault detection delivers measurable value across diverse industries, from manufacturing to energy production, aerospace to healthcare. Each sector benefits from the unmatched accuracy and predictive capabilities these models provide.

Manufacturing and Process Industries

In chemical processing plants, physics-based models monitor reactor conditions, predicting issues like catalyst deactivation, fouling, or runaway reactions. By understanding reaction kinetics, heat transfer, and mass transport, these systems detect subtle deviations indicating emerging problems hours or days before traditional methods.

Semiconductor manufacturing, where precision is paramount, employs physics-based models to maintain tight process control. Plasma etching, deposition, and lithography processes follow well-understood physical principles, enabling models to detect equipment drift that would compromise product quality.

The automotive industry utilizes these models in production line robotics, detecting mechanical degradation in positioning systems before defects appear in manufactured parts. This proactive approach minimizes scrap, reduces quality escapes, and optimizes maintenance schedules.

Energy Sector Innovation

Power generation facilities leverage physics-based models for turbine monitoring, detecting blade cracks, bearing wear, and combustion anomalies. Gas turbines operating at extreme temperatures benefit particularly from thermomechanical models predicting creep, fatigue, and thermal barrier coating degradation.

Wind farms employ structural mechanics models to monitor turbine foundations, towers, and blade integrity. These models account for complex loading conditions from variable wind patterns, detecting fatigue accumulation and structural damage invisible to conventional monitoring.

Nuclear power plants rely on physics-based models for critical safety systems, monitoring reactor core behavior, coolant flow patterns, and pressure vessel integrity. The high-consequence nature of failures in this domain demands the superior accuracy only physics-based approaches provide.

Aerospace and Defense Applications

Aircraft engine manufacturers use physics-based models throughout product lifecycles—from design validation to in-service health monitoring. These models track performance degradation, predict remaining useful life, and optimize maintenance intervals while ensuring safety.

Structural health monitoring systems on airframes employ mechanics-based models to detect fatigue cracks, corrosion, and impact damage. By understanding stress distributions and fracture mechanics, these systems identify critical damage requiring immediate attention while avoiding unnecessary inspections.

Space systems operate in extreme environments where failure consequences are catastrophic and repair opportunities nonexistent. Physics-based models provide the reliability assurance necessary for mission success, predicting component behavior under unprecedented conditions.

🎯 Achieving Unmatched Accuracy: Key Advantages

The superior performance of physics-based models stems from several fundamental advantages that distinguish them from alternative approaches.

Generalization Beyond Training Data

Physics-based models extrapolate accurately to operating conditions never encountered during development. A turbine model understanding aerodynamics and thermodynamics predicts behavior at new operating speeds or ambient conditions without requiring historical data from those exact scenarios.

This capability proves invaluable for rare faults, novel operating modes, and evolving systems. As equipment ages or processes change, physics-based models adapt seamlessly while data-driven models require retraining with new examples.

Interpretability and Root Cause Analysis

When physics-based models detect anomalies, they provide transparent explanations grounded in engineering principles. Instead of merely flagging an issue, these systems identify specific degradation mechanisms, affected components, and probable failure modes.

Maintenance teams receive actionable intelligence: “Bearing temperature elevation consistent with lubrication breakdown” rather than “Anomaly detected in sensor 47.” This clarity accelerates diagnosis, guides repair strategies, and facilitates knowledge transfer across engineering teams.

Early Warning Capabilities

By understanding causal relationships between physical processes, physics-based models detect incipient faults far earlier than symptom-based approaches. They recognize subtle parameter shifts indicating degradation onset, providing extended lead times for intervention.

This early detection transforms maintenance strategies from reactive repairs to proactive replacements, minimizing downtime, preventing secondary damage, and optimizing spare parts inventory. Organizations transition from unplanned shutdowns to scheduled maintenance windows.

🔧 Implementation Strategies for Success

Deploying physics-based fault detection systems requires thoughtful planning, appropriate expertise, and systematic validation to realize their full potential.

Model Development and Validation

Successful implementation begins with accurate system representation. Engineers must select appropriate modeling fidelity—balancing computational complexity against accuracy requirements. Overly simplified models miss critical behaviors; excessively detailed models become computationally prohibitive for real-time applications.

Validation against experimental data or high-fidelity simulations ensures model accuracy across expected operating ranges. This process identifies parameter uncertainties, refines boundary conditions, and establishes confidence bounds on predictions.

Continuous validation using operational data keeps models aligned with actual system behavior as equipment ages and conditions evolve. Adaptive techniques automatically adjust model parameters based on observed performance, maintaining accuracy throughout system lifecycles.

Sensor Infrastructure and Data Integration

Physics-based models require quality input data to generate accurate predictions. Sensor selection must capture relevant physical quantities at appropriate locations, resolutions, and sampling rates. Strategic instrumentation maximizes diagnostic capability while managing costs.

Integration with existing supervisory control and data acquisition (SCADA) systems, historians, and maintenance management software creates seamless information flow. Automated alerting, reporting, and work order generation accelerate response to detected faults.

Edge computing architectures enable complex model execution near monitored equipment, reducing latency and bandwidth requirements while improving reliability. This distributed approach supports real-time control applications where millisecond response times matter.

Organizational Readiness and Training

Technology alone doesn’t guarantee success—organizations must develop competencies to leverage physics-based insights effectively. Training programs should familiarize operators and maintenance personnel with model capabilities, interpretation guidelines, and response protocols.

Establishing clear workflows for anomaly investigation ensures detected faults receive appropriate attention. Escalation procedures, diagnostic checklists, and documentation standards formalize institutional knowledge and continuous improvement.

Cross-functional teams combining domain expertise, modeling specialists, and data scientists optimize system performance. Regular review cycles assess detection accuracy, adjust sensitivity thresholds, and incorporate lessons learned from field experience.

💡 Hybrid Approaches: Combining Physics and Data

The most powerful fault detection systems integrate physics-based models with data-driven techniques, leveraging complementary strengths while mitigating individual weaknesses.

Physics-informed machine learning embeds physical constraints and governing equations into neural network architectures. These hybrid models learn from data while respecting fundamental laws, improving generalization and reducing training data requirements compared to purely empirical approaches.

Data-driven models excel at capturing complex, nonlinear relationships difficult to model from first principles. Combining physics-based predictions with machine learning residual modeling creates systems that understand fundamental behaviors while adapting to system-specific nuances.

Ensemble approaches run multiple models simultaneously—physics-based, statistical, and machine learning—using voting or weighted combination strategies. This diversity improves robustness, as different model types exhibit different failure modes and blind spots.

🚀 Future Directions and Emerging Technologies

The field of physics-based fault detection continues evolving rapidly, driven by computational advances, sensor innovations, and artificial intelligence integration.

Digital twin technology represents the convergence of physics-based modeling, real-time data integration, and immersive visualization. These virtual replicas enable engineers to explore “what-if” scenarios, test maintenance strategies, and optimize system performance risk-free.

Quantum computing promises to revolutionize physics-based simulation, enabling unprecedented model fidelity and real-time execution of complex multiphysics analyses currently requiring hours or days on conventional hardware.

Advanced sensor technologies—including fiber optic strain sensors, wireless sensor networks, and non-contact measurement techniques—expand monitoring capabilities while reducing installation complexity and costs. These developments make physics-based fault detection accessible to smaller systems and applications previously considered economically impractical.

Autonomous systems incorporating physics-based diagnostics into closed-loop control enable self-healing capabilities. Upon detecting faults, these intelligent systems automatically adjust operating parameters, redistribute loads, or activate redundant systems, maintaining performance while alerting human operators.

📊 Measuring Return on Investment

Organizations implementing physics-based fault detection realize tangible benefits across multiple performance dimensions that justify investment costs.

Unplanned downtime reduction represents the most immediate value driver. Early fault detection enables scheduled maintenance during planned outages rather than emergency repairs during production periods. For industries where downtime costs thousands or millions per hour, this benefit alone often justifies system implementation.

Extended equipment life results from addressing degradation proactively before minor issues cascade into major failures. Catching bearing wear early prevents shaft damage; detecting insulation breakdown prevents motor burnout. These avoided secondary damages significantly reduce lifecycle costs.

Improved product quality stems from maintaining equipment within optimal operating ranges. Process variations caused by degrading equipment decrease when faults are detected and corrected promptly, reducing defects and customer complaints.

Optimized maintenance strategies shift resources from time-based preventive maintenance to condition-based approaches. Organizations service equipment when actually needed rather than following conservative schedules, reducing maintenance costs while improving reliability.

🌐 Overcoming Implementation Challenges

Despite compelling benefits, organizations face obstacles when deploying physics-based fault detection systems. Recognizing and addressing these challenges accelerates successful implementation.

Modeling expertise requirements can present barriers, as developing accurate physics-based models demands specialized knowledge. Partnerships with technology vendors, academic institutions, or consultancies help bridge capability gaps during initial deployments while building internal competencies.

Computational requirements for complex models sometimes exceed available infrastructure. Cloud computing platforms and edge processing solutions provide scalable alternatives to large capital investments in computing hardware.

Change management challenges arise as organizations transition from familiar approaches to new methodologies. Demonstrating value through pilot projects, providing comprehensive training, and celebrating early successes build confidence and organizational buy-in.

Data quality and availability issues may limit initial implementation scope. Phased approaches beginning with well-instrumented, critical systems allow organizations to demonstrate value while gradually expanding coverage and refining data collection strategies.

🏆 The Competitive Advantage of Precision

In increasingly competitive global markets, operational excellence separates industry leaders from followers. Physics-based fault detection provides strategic advantages extending beyond immediate maintenance benefits.

Enhanced reliability strengthens customer relationships and brand reputation, particularly in industries where equipment failures impact client operations. Service providers offering superior uptime guarantees capture premium market segments and long-term contracts.

Reduced environmental impact results from preventing catastrophic failures that release hazardous materials or require energy-intensive emergency responses. Proactive maintenance also optimizes energy efficiency by maintaining equipment at peak performance.

Knowledge capture and institutional learning occur as physics-based systems document failure mechanisms, root causes, and effective interventions. This accumulated expertise becomes organizational intellectual property, accelerating technician training and supporting continuous improvement initiatives.

Innovation acceleration follows from deep system understanding. Engineers using physics-based models gain insights driving design improvements, process optimizations, and new product development. The same models used for fault detection inform engineering decisions across product lifecycles.

As industries embrace digital transformation and Industry 4.0 principles, physics-based fault detection stands at the convergence of traditional engineering excellence and cutting-edge technology. Organizations mastering these precision tools position themselves for sustained competitive advantage, operational excellence, and leadership in an increasingly data-driven, performance-focused business environment where accuracy isn’t just desirable—it’s essential for survival.

Toni Santos is a technical researcher and aerospace safety specialist focusing on the study of airspace protection systems, predictive hazard analysis, and the computational models embedded in flight safety protocols. Through an interdisciplinary and data-driven lens, Toni investigates how aviation technology has encoded precision, reliability, and safety into autonomous flight systems — across platforms, sensors, and critical operations. His work is grounded in a fascination with sensors not only as devices, but as carriers of critical intelligence. From collision-risk modeling algorithms to emergency descent systems and location precision mapping, Toni uncovers the analytical and diagnostic tools through which systems preserve their capacity to detect failure and ensure safe navigation. With a background in sensor diagnostics and aerospace system analysis, Toni blends fault detection with predictive modeling to reveal how sensors are used to shape accuracy, transmit real-time data, and encode navigational intelligence. As the creative mind behind zavrixon, Toni curates technical frameworks, predictive safety models, and diagnostic interpretations that advance the deep operational ties between sensors, navigation, and autonomous flight reliability. His work is a tribute to: The predictive accuracy of Collision-Risk Modeling Systems The critical protocols of Emergency Descent and Safety Response The navigational precision of Location Mapping Technologies The layered diagnostic logic of Sensor Fault Detection and Analysis Whether you're an aerospace engineer, safety analyst, or curious explorer of flight system intelligence, Toni invites you to explore the hidden architecture of navigation technology — one sensor, one algorithm, one safeguard at a time.