Low-cost sensors have revolutionized how industries collect data, but their affordability often comes with reliability challenges that demand innovative fault detection strategies.

🔍 The Growing Landscape of Budget-Friendly Sensing Technology

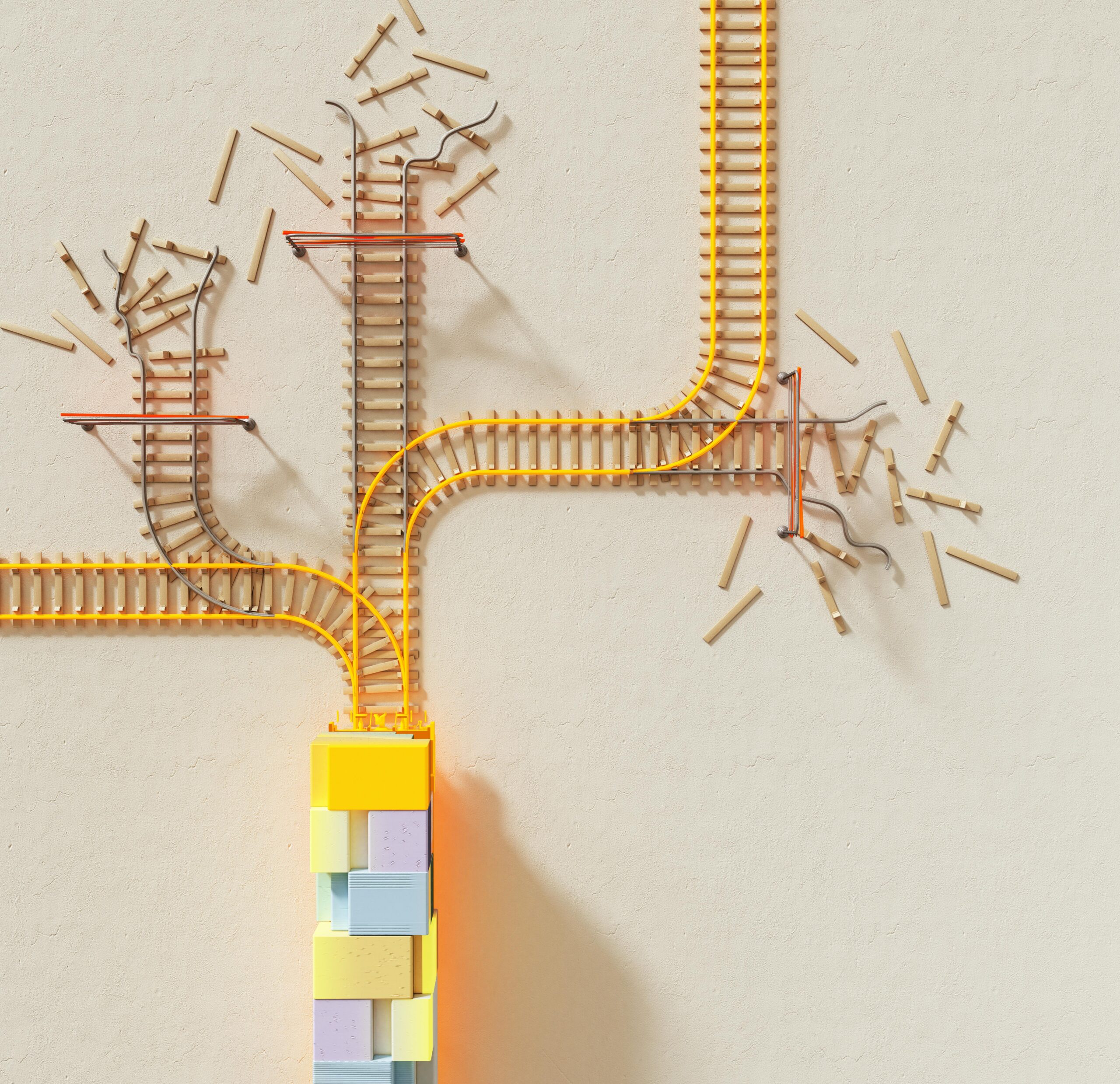

The proliferation of low-cost sensors across industries has fundamentally transformed data collection practices. From agricultural monitoring systems to smart city infrastructure, these affordable devices enable unprecedented access to real-time information. However, their accessibility introduces a critical challenge: maintaining data integrity when hardware limitations create vulnerabilities to failures, drift, and environmental interference.

Organizations increasingly deploy hundreds or thousands of sensors simultaneously, making manual monitoring impractical. A single faulty sensor can cascade into flawed decision-making, compromised safety protocols, or operational inefficiencies costing far more than the sensor’s initial price. This reality necessitates automated fault detection systems that match the economic profile of the sensors themselves.

The sensor market has expanded exponentially, with temperature, humidity, pressure, and gas sensors now available at price points below five dollars per unit. This democratization of sensing technology empowers small businesses, research institutions, and developing regions to participate in the Internet of Things revolution. Yet affordability shouldn’t mean compromising on data quality or system reliability.

💡 Understanding Common Failure Modes in Economical Sensors

Before implementing detection strategies, identifying typical failure patterns becomes essential. Low-cost sensors exhibit predictable degradation characteristics that differ significantly from their industrial-grade counterparts.

Calibration Drift and Environmental Sensitivity

Budget sensors frequently experience calibration drift over time, particularly when exposed to temperature fluctuations or humidity variations. A temperature sensor that initially provides accurate readings within ±0.5°C might gradually shift to ±2°C or more without physical damage. This subtle degradation often escapes notice until data analysis reveals systematic errors.

Environmental factors accelerate this process. Condensation affects humidity sensors, dust accumulation impacts optical devices, and chemical exposure degrades gas sensors. Unlike premium alternatives with protective housings and compensation circuits, affordable options sacrifice these features for cost reduction.

Intermittent Connection Failures

Communication interfaces represent another vulnerability point. Inexpensive sensors typically employ basic connection protocols without robust error-checking mechanisms. Wireless sensors especially suffer from signal interference, battery depletion, and range limitations that create sporadic data gaps.

These intermittent failures prove particularly troublesome because they appear random rather than systematic. A sensor might function perfectly for days before suddenly dropping offline for hours, then resuming normal operation without intervention.

Complete Component Failure

Outright sensor death, while easier to detect than subtle drift, still requires systematic identification. Dead sensors stop transmitting data entirely, but in large networks, distinguishing between communication problems and hardware failure demands intelligent analysis.

🛠️ Cost-Effective Detection Strategies That Actually Work

Implementing fault detection doesn’t require enterprise-level budgets. Several proven approaches balance effectiveness with affordability, making them suitable for projects constrained by economic realities.

Statistical Process Control Techniques

Statistical methods provide powerful detection capabilities without additional hardware investments. By establishing baseline performance metrics, systems can identify anomalies automatically. Control charts track sensor outputs over time, flagging values exceeding predetermined thresholds.

The simplest implementation monitors mean and standard deviation windows. When a sensor’s readings deviate significantly from historical patterns or neighboring sensors, the system raises alerts. This approach requires minimal computational resources and adapts to various sensor types.

Moving average calculations smooth out noise while highlighting sustained drift. A sensor gradually reading higher temperatures than surrounding units indicates potential calibration issues rather than environmental changes. The computational overhead remains minimal, making this suitable even for microcontroller-based systems.

Spatial Correlation Analysis

When multiple sensors monitor similar environments, their readings should correlate predictably. A temperature sensor array in a warehouse should show gradual variations, not isolated spikes. Spatial correlation algorithms compare each sensor against its neighbors, identifying outliers that suggest malfunctions.

This technique proves particularly effective because it leverages redundancy inherent in many deployments. Smart agriculture applications might place dozens of soil moisture sensors across fields. If one reports drastically different values than adjacent units without corresponding environmental explanations, fault probability increases significantly.

Implementation requires establishing correlation matrices during initial calibration periods. The system learns normal variation patterns, then continuously evaluates whether current readings fall within expected ranges based on neighboring sensor data.

Temporal Pattern Recognition

Sensor data exhibits temporal patterns reflecting natural cycles—diurnal temperature variations, weekly occupancy patterns, seasonal humidity changes. Deviations from these learned patterns indicate potential problems.

Machine learning models, even simple ones, excel at recognizing these patterns. Long Short-Term Memory networks or basic regression models predict expected values based on historical data. When actual readings diverge significantly from predictions, the system flags potential faults.

The beauty of this approach lies in its self-improving nature. As more data accumulates, prediction accuracy increases, enabling detection of increasingly subtle anomalies. Initial training requires only a few weeks of baseline data collection.

📊 Building a Practical Correction Framework

Detection identifies problems, but correction maintains system functionality. Several strategies enable continued operation despite sensor faults, minimizing downtime and maintaining data quality.

Software-Based Calibration Adjustment

When drift rather than complete failure occurs, software corrections often suffice. By comparing faulty sensors against reliable references or neighboring units, systems calculate correction factors applied to subsequent readings.

This approach extends sensor lifespan considerably. A temperature sensor drifting by 1.5°C remains useful if the system automatically subtracts this offset. Periodic recalibration updates these correction factors, maintaining accuracy without physical replacement.

Implementing this requires establishing ground truth references—either through periodic manual measurements or maintaining a subset of higher-quality calibrated sensors as benchmarks. The cost of a few reference sensors justifies extending the operational life of hundreds of budget units.

Data Imputation and Reconstruction

When sensors fail completely or temporarily, statistical imputation fills gaps. Multiple techniques exist, ranging from simple interpolation to sophisticated algorithms leveraging spatial and temporal correlations.

Linear interpolation works for brief outages, estimating missing values based on readings immediately before and after the gap. For extended failures, more complex methods use neighboring sensors and historical patterns. Kriging algorithms, borrowed from geostatistics, provide spatially-aware interpolation accounting for distance and correlation relationships.

The key consideration involves transparency. Systems should clearly mark imputed data, distinguishing it from actual measurements. This enables downstream users to make informed decisions about data reliability for their specific applications.

Automated Sensor Substitution

In critical applications, redundancy provides the ultimate insurance. Deploying multiple sensors at strategic locations allows automatic failover when faults occur. The system detects a malfunctioning unit and seamlessly switches to backup sensors without human intervention.

This approach increases upfront costs but dramatically improves reliability. For applications where data gaps create significant consequences—safety monitoring, critical infrastructure, medical devices—the investment justifies the protection against failures.

⚙️ Implementing Solutions with Open-Source Tools

Budget-conscious projects benefit enormously from the open-source ecosystem. Numerous platforms and libraries provide robust fault detection capabilities without licensing fees.

Python Libraries for Data Analysis

Python’s scientific computing stack offers everything needed for sophisticated fault detection. NumPy handles numerical computations efficiently, Pandas manages time-series data, and SciPy provides statistical functions. Scikit-learn delivers machine learning capabilities for pattern recognition and anomaly detection.

These tools run on modest hardware. A Raspberry Pi 4 possesses sufficient processing power to monitor hundreds of sensors in real-time, applying statistical analysis and machine learning models. The development environment costs under $100, making it accessible to educational institutions, hobbyists, and startups.

Sample implementations abound online, reducing development time. Repositories on GitHub contain complete fault detection systems adaptable to specific requirements. Communities provide support, troubleshooting assistance, and continuous improvements.

Edge Computing Architectures

Processing data near its source reduces latency, bandwidth requirements, and cloud computing costs. Edge devices perform initial fault detection locally, transmitting only alerts or aggregated data to central servers.

Microcontrollers like ESP32 modules cost under $10 yet incorporate WiFi connectivity and sufficient processing for basic statistical analysis. These devices implement first-stage detection, identifying obvious faults before data reaches more sophisticated analysis layers.

This tiered architecture scales efficiently. Simple rules execute on sensor nodes, intermediate analysis occurs on edge gateways, and complex machine learning models run on cloud infrastructure only when necessary. The distribution optimizes cost, power consumption, and response time simultaneously.

Cloud Platforms for Scalable Monitoring

When local processing proves insufficient, cloud platforms offer scalable solutions. Services like AWS IoT Core, Google Cloud IoT, and Microsoft Azure IoT Hub provide managed infrastructure for sensor networks.

These platforms include built-in anomaly detection services leveraging machine learning. While commercial, their pricing models accommodate small deployments affordably. Free tiers and pay-per-use billing enable starting small and scaling as projects grow.

Open-source alternatives like ThingsBoard and Node-RED provide self-hosted options. Organizations with existing server infrastructure deploy these platforms without recurring subscription costs, maintaining complete data control.

🎯 Real-World Applications Demonstrating Success

Theory becomes tangible through practical examples. Numerous organizations have implemented affordable fault detection with impressive results.

Agricultural Monitoring Systems

Smart farming operations deploy extensive sensor networks monitoring soil conditions, weather parameters, and crop health. A vineyard in California implemented fault detection across 500 low-cost soil moisture sensors using spatial correlation analysis.

The system reduced false irrigation events by 78%, saving water and preventing crop damage. When sensors drifted due to soil chemistry changes, automatic calibration adjustments maintained accuracy. The entire fault detection infrastructure cost less than $2,000 beyond the sensors themselves, paying for itself within a single growing season.

Building Energy Management

A university campus deployed 1,200 temperature and occupancy sensors to optimize HVAC systems. Fault detection identified 15% of sensors experiencing drift or failure within six months. Automated correction maintained system performance while maintenance teams systematically replaced problematic units during scheduled building access.

Energy savings exceeded 22% compared to the previous manual monitoring approach. The detection system cost approximately $0.50 per sensor to implement, using existing network infrastructure and open-source software on a dedicated server.

Air Quality Monitoring Networks

Community air quality initiatives often rely on citizen-deployed low-cost sensors. A project in Southeast Asia addressed data quality concerns by implementing crowdsourced calibration. Participants periodically collocated sensors with reference stations, generating correction factors applied retroactively to historical data.

This approach improved data reliability while maintaining the project’s grassroots nature. Fault detection identified sensors requiring recalibration, guiding participants to reference stations. The combination of technical solutions and community engagement created sustainable monitoring networks costing a fraction of traditional approaches.

🚀 Future-Proofing Sensor Networks

Technology evolves rapidly, and fault detection strategies must adapt accordingly. Several emerging trends promise enhanced capabilities at continued affordability.

Machine Learning at the Edge

Recent microcontroller generations incorporate hardware acceleration for neural network inference. TinyML techniques compress sophisticated models to run on resource-constrained devices. This enables individual sensors to perform local anomaly detection, reducing dependence on connectivity and central processing.

Development frameworks like TensorFlow Lite for Microcontrollers democratize this capability. Engineers without deep machine learning expertise can deploy pre-trained models or train custom ones using simplified interfaces.

Peer-to-Peer Sensor Networks

Decentralized architectures eliminate single points of failure. Sensors communicate directly with neighbors, collectively identifying faults through distributed consensus algorithms. This approach proves particularly valuable in remote deployments where internet connectivity proves unreliable or expensive.

Blockchain-inspired techniques ensure data integrity and create tamper-evident audit trails. While full blockchain implementation remains impractical for resource-constrained sensors, lightweight adaptations preserve core benefits without computational overhead.

Digital Twin Integration

Virtual models simulating physical environments provide powerful fault detection capabilities. A digital twin predicts expected sensor readings based on physics-based models. Discrepancies between predictions and actual measurements indicate potential faults or interesting environmental changes requiring investigation.

Creating digital twins once required expensive specialized software, but open-source tools and simplified modeling approaches make this accessible. Even approximate models provide valuable reference points for fault detection algorithms.

💰 Calculating Return on Investment

Budget constraints demand justifying every expenditure. Fault detection systems deliver measurable value through multiple mechanisms.

Direct cost savings emerge from extended sensor lifespan. Early detection of calibration drift enables correction before complete failure, potentially doubling operational life. With sensors deployed by thousands, these extensions accumulate substantial savings.

Operational efficiency improvements provide another benefit stream. Accurate data enables better decision-making, whether optimizing energy consumption, irrigation scheduling, or production processes. Case studies consistently demonstrate returns exceeding 3:1 within the first year.

Risk mitigation represents harder-to-quantify but equally important value. Preventing a single safety incident or production disruption often justifies the entire fault detection investment. Insurance implications and liability considerations make reliability investments prudent business decisions.

🔧 Practical Implementation Roadmap

Successful deployment follows structured phases, each building upon previous foundations.

Begin with baseline data collection, establishing normal operational patterns. Deploy sensors and simply record data for 2-4 weeks without fault detection active. This period generates training data for statistical models and machine learning algorithms.

Implement simple rule-based detection first. Establish thresholds for obvious failures—missing data, physically impossible readings, or values exceeding equipment specifications. These catches low-hanging fruit, providing immediate value while more sophisticated systems develop.

Gradually introduce statistical and correlation-based detection. Start with conservative thresholds to minimize false positives, then tune based on operational experience. Document actual faults discovered, building institutional knowledge about failure modes specific to your deployment.

Develop correction strategies in parallel. Establish protocols for manual intervention initially, then automate responses as confidence grows. Create clear escalation paths for different fault severities, ensuring appropriate human oversight remains in critical decisions.

Continuously monitor system performance. Track metrics like detection rate, false positive percentage, and response time. Iterate improvements based on lessons learned, gradually enhancing sophistication as justified by operational needs.

🌟 Empowering Innovation Through Accessible Technology

Affordable sensors democratize data collection, but only reliable data enables sound decisions. Fault detection transforms potentially unreliable measurements into trustworthy information streams supporting critical applications. The techniques and tools described here place sophisticated capabilities within reach of organizations regardless of budget scale.

Success requires balancing technical sophistication with practical constraints. Not every deployment needs cutting-edge machine learning—sometimes simple statistical methods suffice. The key lies in matching detection strategy to specific requirements, reliability demands, and available resources.

As sensor costs continue declining and open-source tools mature, the gap between budget and premium deployments narrows. Organizations implementing thoughtful fault detection today position themselves advantageously for tomorrow’s increasingly sensor-rich environments. The investment in reliability infrastructure pays dividends through enhanced decision-making, operational efficiency, and competitive advantage.

Low-cost sensors need not mean low-quality data. With appropriate detection and correction strategies, affordable hardware delivers performance approaching premium alternatives at a fraction of the cost. This accessibility unleashes innovation, enabling applications previously considered economically unfeasible and extending technology’s benefits to underserved communities and resource-constrained organizations worldwide.

Toni Santos is a technical researcher and aerospace safety specialist focusing on the study of airspace protection systems, predictive hazard analysis, and the computational models embedded in flight safety protocols. Through an interdisciplinary and data-driven lens, Toni investigates how aviation technology has encoded precision, reliability, and safety into autonomous flight systems — across platforms, sensors, and critical operations. His work is grounded in a fascination with sensors not only as devices, but as carriers of critical intelligence. From collision-risk modeling algorithms to emergency descent systems and location precision mapping, Toni uncovers the analytical and diagnostic tools through which systems preserve their capacity to detect failure and ensure safe navigation. With a background in sensor diagnostics and aerospace system analysis, Toni blends fault detection with predictive modeling to reveal how sensors are used to shape accuracy, transmit real-time data, and encode navigational intelligence. As the creative mind behind zavrixon, Toni curates technical frameworks, predictive safety models, and diagnostic interpretations that advance the deep operational ties between sensors, navigation, and autonomous flight reliability. His work is a tribute to: The predictive accuracy of Collision-Risk Modeling Systems The critical protocols of Emergency Descent and Safety Response The navigational precision of Location Mapping Technologies The layered diagnostic logic of Sensor Fault Detection and Analysis Whether you're an aerospace engineer, safety analyst, or curious explorer of flight system intelligence, Toni invites you to explore the hidden architecture of navigation technology — one sensor, one algorithm, one safeguard at a time.