Sensors power modern technology, but their reliability hinges on understanding four critical failure modes: drift, bias, dropout, and noise. These issues compromise data quality and system performance.

🔍 The Hidden Challenges in Sensor Technology

Modern industrial systems, IoT devices, medical equipment, and autonomous vehicles depend heavily on sensors to collect accurate real-time data. However, sensors are not infallible instruments. They face numerous challenges that can significantly degrade measurement quality and lead to catastrophic system failures if left unaddressed.

Understanding sensor anomalies is crucial for engineers, data scientists, and system designers who rely on sensor data for critical decision-making processes. The four primary sensor issues—drift, bias, dropout, and noise—each present unique characteristics and require specific mitigation strategies.

This comprehensive exploration delves into these sensor snags, examining their causes, impacts, detection methods, and practical solutions to maintain optimal performance across diverse applications.

📊 Sensor Drift: The Gradual Performance Decline

Sensor drift represents a progressive change in sensor output over time, even when measuring the same constant input. This phenomenon occurs gradually and can be particularly insidious because it develops slowly enough to evade immediate detection.

Understanding the Root Causes of Drift

Several factors contribute to sensor drift. Component aging is perhaps the most common cause, as electronic components naturally degrade over time due to thermal cycling, mechanical stress, and chemical reactions within materials. Temperature variations also play a significant role, with sensors experiencing different thermal coefficients that alter their calibration points.

Environmental contamination, including dust accumulation, humidity exposure, and chemical deposits, can progressively alter sensor surfaces and affect their measurement capabilities. Mechanical wear in sensors with moving parts accelerates drift through friction and material fatigue.

Real-World Impact of Sensor Drift

In industrial process control, temperature sensor drift can lead to products being manufactured outside specification ranges, resulting in quality issues and wasted materials. Medical devices like blood glucose monitors experiencing drift can provide dangerously inaccurate readings, potentially compromising patient safety.

Autonomous vehicles rely on multiple sensors working in harmony. When LiDAR or radar sensors drift, distance calculations become increasingly inaccurate, threatening collision avoidance systems. Environmental monitoring stations with drifting sensors can provide misleading data about air quality or water contamination levels.

Detection and Mitigation Strategies

Implementing regular calibration schedules represents the most straightforward approach to managing drift. Organizations should establish calibration intervals based on manufacturer specifications, operating conditions, and criticality of measurements.

Redundant sensor arrays allow systems to compare multiple sensors measuring the same parameter. When one sensor’s readings diverge significantly from others, drift becomes detectable. Statistical process control methods, including cumulative sum (CUSUM) charts, can identify subtle trending patterns indicative of drift before they become problematic.

Advanced machine learning algorithms now enable predictive drift detection, analyzing historical sensor behavior patterns to anticipate when recalibration will be necessary. This proactive approach minimizes downtime and maintains measurement integrity.

⚖️ Sensor Bias: The Systematic Measurement Error

Unlike drift, which develops over time, sensor bias represents a consistent offset from true values. A biased sensor systematically reads high or low across its entire measurement range, introducing a constant error that affects all readings.

Origins of Systematic Bias

Calibration errors during manufacturing or installation create the most common source of bias. When sensors are improperly zeroed or calibrated against incorrect reference standards, they perpetuate systematic errors throughout their operational life.

Installation position and orientation can introduce bias, particularly in sensors measuring gravity-dependent parameters like accelerometers and pressure sensors. Environmental factors, such as consistent electromagnetic interference or thermal gradients, can also create bias conditions.

Design limitations sometimes introduce inherent bias. For example, strain gauges measuring force may exhibit bias due to mounting stress, while optical sensors can show bias from ambient light contamination.

Identifying and Correcting Bias

Bias detection requires comparison against known reference standards or gold-standard measurement instruments. Regular verification using traceable calibration sources helps identify and quantify bias magnitude.

Software compensation provides an effective solution for consistent bias. Once identified, offset corrections can be programmed into data acquisition systems, automatically adjusting raw sensor readings to account for known bias.

Physical recalibration remains the most thorough approach. This involves adjusting sensor zero points and gain settings to align output with reference standards across the measurement range.

⚡ Signal Dropout: When Sensors Go Silent

Dropout occurs when sensors temporarily or permanently stop providing data. This complete loss of signal presents unique challenges because systems suddenly receive no information rather than incorrect information.

Common Dropout Scenarios

Intermittent electrical connections represent frequent dropout culprits. Loose wiring, corroded contacts, or vibration-induced disconnections cause sensors to periodically lose power or communication pathways.

Software glitches in sensor firmware or data acquisition systems can trigger dropout events. Buffer overflows, timing conflicts, or communication protocol errors may interrupt data flow without physical hardware failures.

Environmental extremes sometimes push sensors beyond operational limits, causing temporary shutdown. Extreme temperatures, moisture ingress, or excessive mechanical shock can trigger protective modes or cause temporary malfunctions.

Wireless sensors face additional dropout risks from signal interference, range limitations, and power depletion. Radio frequency congestion or physical obstructions can interrupt communication links.

Managing Dropout Risks

Implementing watchdog timers and heartbeat signals enables systems to detect dropout conditions quickly. When expected data packets fail to arrive within specified intervals, systems can trigger alarms and initiate fallback procedures.

Data buffering strategies help bridge temporary dropout events. Local storage captures sensor data during communication interruptions, transmitting accumulated data when connections restore.

Redundant sensor configurations provide the most robust dropout protection. Critical measurements should employ multiple independent sensors, allowing systems to continue operating when individual sensors fail.

Graceful degradation algorithms enable systems to maintain reduced functionality during dropout events rather than complete failure. For example, navigation systems might switch to dead reckoning when GPS signals drop out.

🌊 Sensor Noise: Understanding Random Fluctuations

Noise represents random variations in sensor output that obscure true signal values. Unlike drift and bias, which show patterns, noise appears as unpredictable fluctuations around the actual measurement.

Types and Sources of Sensor Noise

Thermal noise, also called Johnson-Nyquist noise, arises from random electron movement in conductors and increases with temperature. This fundamental physics phenomenon affects all electronic sensors to varying degrees.

Shot noise results from the discrete nature of electrical charge, creating random fluctuations in current flow. Particularly prominent in photodetectors and semiconductor devices, shot noise increases with signal magnitude.

Electromagnetic interference (EMI) introduces externally-sourced noise. Motors, power lines, radio transmitters, and switching power supplies can couple unwanted signals into sensitive sensor circuits.

Quantization noise emerges from analog-to-digital conversion, where continuous signals must be represented using discrete digital values. Lower-resolution converters produce more quantization noise.

Noise Characterization and Analysis

Signal-to-noise ratio (SNR) quantifies noise severity, comparing desired signal strength to background noise levels. Higher SNR values indicate cleaner signals with better measurement quality.

Frequency domain analysis using Fast Fourier Transform (FFT) reveals noise characteristics. White noise appears uniform across frequencies, while colored noise shows frequency-dependent patterns that may indicate specific interference sources.

Statistical measures including standard deviation and variance provide quantitative noise assessments. These metrics help establish confidence intervals for measurements and determine when noise levels exceed acceptable thresholds.

Practical Noise Reduction Techniques

Hardware filtering represents the first line of defense against noise. Low-pass filters remove high-frequency noise components, while notch filters target specific interference frequencies like 50/60 Hz power line noise.

Proper grounding and shielding practices minimize EMI pickup. Twisted pair wiring, shielded cables, and careful attention to ground loops significantly reduce external noise coupling.

Signal averaging improves SNR by combining multiple measurements. Since noise varies randomly while true signal values remain constant, averaging reduces noise amplitude proportional to the square root of sample count.

Digital filtering techniques, including moving average filters, median filters, and sophisticated algorithms like Kalman filters, extract true signals from noisy data. These computational approaches can adapt to changing noise characteristics.

🛠️ Integrated Diagnostic Approaches

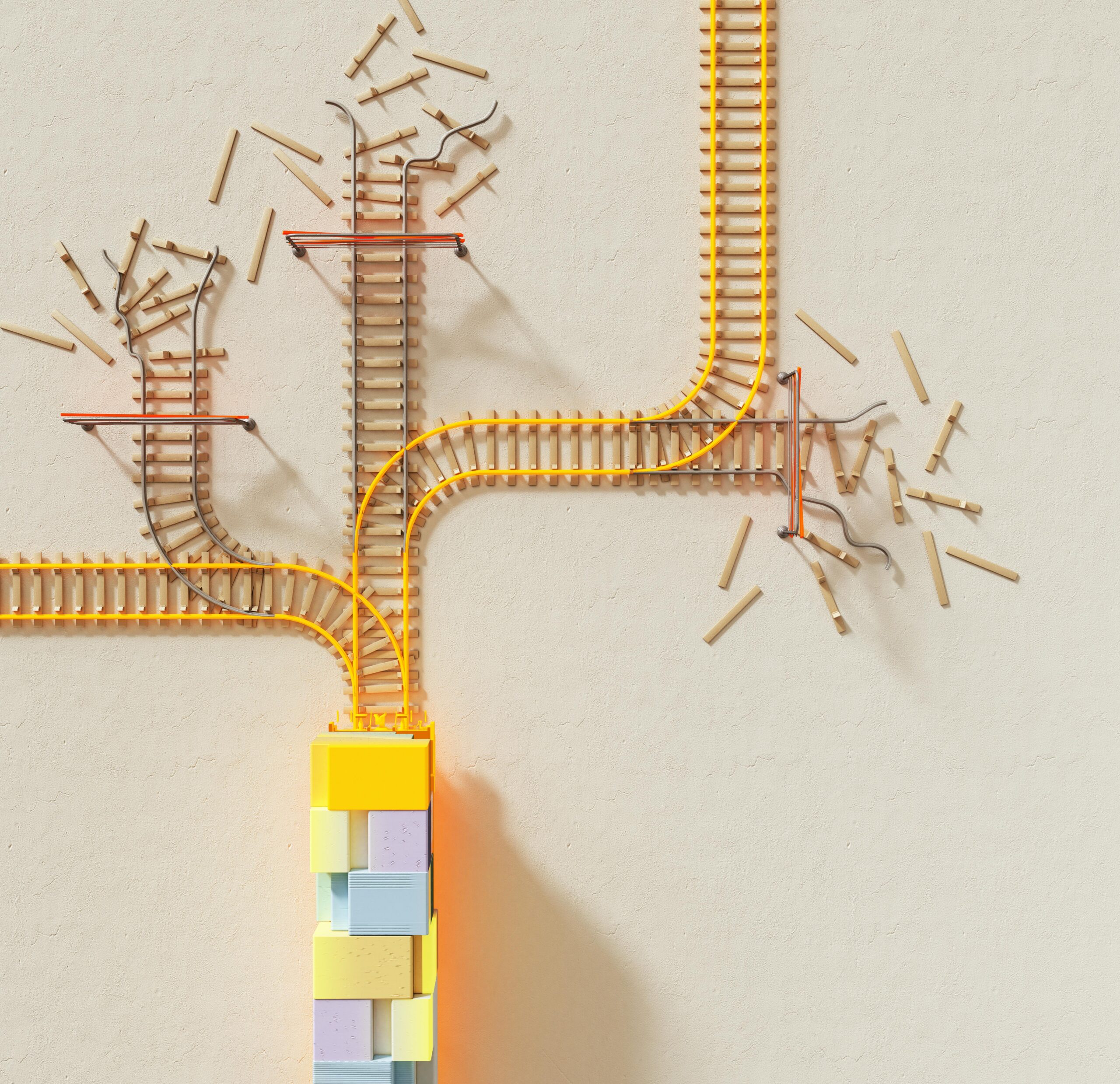

Real-world sensor systems often experience multiple issues simultaneously. Comprehensive diagnostic strategies must address drift, bias, dropout, and noise collectively rather than treating them as isolated problems.

Multi-Sensor Fusion Techniques

Sensor fusion combines data from multiple sensors to produce more accurate and reliable measurements than any single sensor provides. This approach naturally mitigates individual sensor failures, dropout events, and noise through redundancy and cross-validation.

Complementary sensor pairing leverages different sensor technologies measuring related parameters. For instance, combining accelerometer and gyroscope data produces more stable orientation estimates than either sensor alone.

Automated Health Monitoring Systems

Modern sensor networks increasingly incorporate self-diagnostic capabilities. Built-in test (BIT) routines periodically verify sensor functionality, checking for drift, bias, and excessive noise levels.

Anomaly detection algorithms continuously analyze sensor behavior patterns, flagging deviations that might indicate developing problems. Machine learning models trained on historical data can distinguish normal operational variations from genuine sensor degradation.

💡 Industry-Specific Considerations

Different application domains face unique sensor challenges requiring tailored solutions.

Manufacturing and Process Control

Industrial environments subject sensors to harsh conditions including extreme temperatures, vibration, chemical exposure, and electromagnetic interference. Robust sensor selection, protective enclosures, and frequent calibration maintain measurement quality.

Predictive maintenance strategies monitor sensor health alongside production equipment, scheduling calibration during planned downtime to minimize production disruptions.

Medical and Healthcare Applications

Patient safety demands exceptional sensor reliability. Medical devices undergo rigorous validation and require frequent calibration verification. Redundant measurements and automated quality checks provide additional safety layers.

Single-use sensors eliminate drift and contamination concerns but require consistent manufacturing quality. Reusable sensors need comprehensive cleaning and verification protocols between uses.

Automotive and Autonomous Systems

Vehicles operate across extreme environmental ranges while maintaining safety-critical functions. Sensor fusion, redundancy, and sophisticated fault detection enable reliable operation despite individual sensor failures.

Over-the-air updates allow manufacturers to improve sensor algorithms and compensation strategies throughout vehicle lifetimes, addressing issues discovered post-production.

🚀 Emerging Technologies and Future Directions

Sensor technology continues advancing rapidly, with new approaches addressing traditional performance limitations.

Self-Calibrating Sensors

Next-generation sensors incorporate reference elements and automated calibration routines, maintaining accuracy without external intervention. These intelligent devices detect drift and bias, applying automatic corrections.

AI-Enhanced Signal Processing

Deep learning algorithms excel at extracting meaningful signals from noisy, corrupted data. Neural networks trained on extensive datasets can identify and compensate for various sensor anomalies with minimal human intervention.

Quantum Sensing Technologies

Quantum sensors leverage quantum mechanical phenomena to achieve unprecedented sensitivity and stability. These emerging technologies promise measurements with minimal drift and noise, though practical implementations remain challenging.

🎯 Building Robust Sensor Systems

Achieving optimal sensor performance requires holistic system design considering hardware selection, installation practices, signal conditioning, data processing, and maintenance strategies.

Specification-driven sensor selection ensures chosen devices meet application requirements with appropriate margins. Understanding operating conditions, required accuracy, and reliability expectations guides technology choices.

Professional installation following manufacturer guidelines prevents bias introduction and minimizes environmental stress. Proper mounting, wiring practices, and environmental protection extend sensor life.

Comprehensive testing and validation before deployment identifies problems early. Acceptance testing verifies performance against specifications, while environmental stress screening reveals infant mortality failures.

Ongoing monitoring and maintenance preserve long-term performance. Regular calibration, cleaning, and inspection catch degradation before it compromises operations.

🔬 Data Quality Assurance Frameworks

Systematic data quality assurance transforms raw sensor outputs into trustworthy information for decision-making. Multi-layered validation catches various failure modes.

Range checking flags physically impossible values indicating sensor failures or communication errors. Consistency checks compare related measurements, identifying contradictions that suggest problems.

Temporal validation examines measurement sequences for unrealistic rate changes or discontinuities. Spatial correlation in sensor networks reveals localized failures when neighboring sensors disagree.

Statistical quality control establishes normal operating ranges, triggering alerts when measurements exhibit unusual patterns. These techniques distinguish genuine process changes from sensor problems.

⚙️ Practical Implementation Guidelines

Organizations seeking to optimize sensor system performance should follow structured approaches addressing all aspects of sensor lifecycle management.

Develop comprehensive sensor inventories documenting specifications, locations, calibration requirements, and maintenance histories. This foundation enables systematic quality management.

Establish clear performance criteria defining acceptable accuracy, precision, and reliability levels for each application. These specifications guide selection, validation, and maintenance decisions.

Implement layered diagnostics combining automated monitoring, periodic manual verification, and comprehensive calibration programs. This defense-in-depth approach catches problems multiple ways.

Foster cross-functional collaboration between operations, maintenance, engineering, and quality teams. Sensor performance impacts multiple stakeholders who must coordinate efforts.

Invest in training ensuring personnel understand sensor principles, failure modes, and diagnostic techniques. Knowledgeable teams respond more effectively to problems.

Continuously improve sensor strategies by analyzing failure patterns, incorporating lessons learned, and adopting emerging best practices and technologies.

By thoroughly understanding sensor drift, bias, dropout, and noise while implementing comprehensive management strategies, organizations can achieve optimal sensor system performance. These efforts translate directly into improved product quality, enhanced safety, reduced downtime, and better decision-making across applications relying on accurate, reliable sensor data.

Toni Santos is a technical researcher and aerospace safety specialist focusing on the study of airspace protection systems, predictive hazard analysis, and the computational models embedded in flight safety protocols. Through an interdisciplinary and data-driven lens, Toni investigates how aviation technology has encoded precision, reliability, and safety into autonomous flight systems — across platforms, sensors, and critical operations. His work is grounded in a fascination with sensors not only as devices, but as carriers of critical intelligence. From collision-risk modeling algorithms to emergency descent systems and location precision mapping, Toni uncovers the analytical and diagnostic tools through which systems preserve their capacity to detect failure and ensure safe navigation. With a background in sensor diagnostics and aerospace system analysis, Toni blends fault detection with predictive modeling to reveal how sensors are used to shape accuracy, transmit real-time data, and encode navigational intelligence. As the creative mind behind zavrixon, Toni curates technical frameworks, predictive safety models, and diagnostic interpretations that advance the deep operational ties between sensors, navigation, and autonomous flight reliability. His work is a tribute to: The predictive accuracy of Collision-Risk Modeling Systems The critical protocols of Emergency Descent and Safety Response The navigational precision of Location Mapping Technologies The layered diagnostic logic of Sensor Fault Detection and Analysis Whether you're an aerospace engineer, safety analyst, or curious explorer of flight system intelligence, Toni invites you to explore the hidden architecture of navigation technology — one sensor, one algorithm, one safeguard at a time.