Fault detection systems are the backbone of modern industrial operations, ensuring efficiency, safety, and minimal downtime across sectors from manufacturing to telecommunications. ⚙️

As industries become increasingly complex and data-rich, the methods used to identify anomalies and prevent failures have evolved dramatically. Today, organizations face a critical decision: should they rely on traditional rule-based systems that have proven their worth over decades, or embrace the cutting-edge capabilities of machine learning-based approaches that promise unprecedented accuracy and adaptability?

This question isn’t merely academic—it has profound implications for operational costs, system reliability, and competitive advantage. The choice between rule-based and ML-based fault detection can determine whether your organization stays ahead of problems or constantly plays catch-up with failures.

🔍 Understanding Rule-Based Fault Detection Systems

Rule-based fault detection represents the traditional approach to identifying system anomalies. These systems operate on explicitly programmed logic—if-then conditions that trigger alerts when specific thresholds are crossed or particular patterns emerge. Think of them as digital sentinels following a predetermined instruction manual.

The foundation of rule-based systems lies in domain expertise. Engineers and operators who understand equipment behavior define specific conditions that indicate potential failures. For example, a rule might state: “If motor temperature exceeds 85°C for more than 5 minutes, trigger an alert.” These rules are transparent, predictable, and directly tied to known failure mechanisms.

Industries have relied on rule-based systems for good reason. They deliver consistent performance, require minimal computational resources, and provide interpretability that regulatory environments often demand. When an alert fires, operators know exactly which condition was violated, making troubleshooting straightforward.

The Strengths That Keep Rule-Based Systems Relevant

Rule-based fault detection excels in environments where failure modes are well-understood and relatively stable. Manufacturing processes with consistent operating conditions benefit tremendously from this approach. The transparency of rule-based systems means that when a fault is detected, the cause is immediately apparent—there’s no “black box” to interrogate.

Implementation costs for rule-based systems are typically lower upfront. Organizations don’t need extensive historical data or specialized data science teams. Maintenance engineers can often create and modify rules based on their operational knowledge, enabling rapid deployment and adjustment.

Regulatory compliance represents another significant advantage. Industries like pharmaceuticals, nuclear energy, and aviation operate under strict oversight where decision-making processes must be fully explainable. Rule-based systems provide audit trails that clearly show why specific actions were taken, satisfying regulatory requirements that ML systems often struggle to meet.

🤖 The Machine Learning Revolution in Fault Detection

Machine learning-based fault detection represents a paradigm shift in how we identify and predict system failures. Rather than relying on predefined rules, ML systems learn patterns directly from data, discovering relationships that human experts might overlook or that are too complex to encode manually.

These systems analyze vast quantities of sensor data, identifying subtle correlations and temporal patterns that precede failures. An ML model might discover that a specific combination of vibration frequency, temperature variation, and pressure fluctuation predicts bearing failure three days in advance—a relationship too nuanced for traditional rule-based approaches.

The learning capability of ML systems means they adapt to changing conditions. As equipment ages, operational patterns shift, or new failure modes emerge, the models can be retrained to maintain accuracy. This adaptability addresses one of the fundamental limitations of static rule-based systems.

Machine Learning Techniques Transforming Fault Detection

Several ML approaches have proven particularly effective for fault detection. Supervised learning algorithms like Random Forests and Support Vector Machines excel when labeled failure data is available, learning to classify normal versus abnormal operating states with high accuracy.

Unsupervised learning techniques, particularly anomaly detection algorithms, identify deviations from normal patterns without requiring labeled failure examples. This capability is invaluable for detecting novel fault types that haven’t been explicitly programmed or previously encountered.

Deep learning neural networks have pushed boundaries further, automatically extracting hierarchical features from raw sensor data. Recurrent neural networks and Long Short-Term Memory (LSTM) models capture temporal dependencies in time-series data, recognizing patterns that unfold over hours or days before a failure occurs.

⚖️ Comparing Performance: Precision, Recall, and Real-World Impact

When evaluating fault detection systems, performance metrics tell only part of the story. Precision—the proportion of detected faults that are genuine—matters immensely because false alarms waste resources and erode operator trust. Recall—the proportion of actual faults successfully detected—is equally critical, as missed failures can lead to catastrophic outcomes.

Rule-based systems typically deliver high precision when rules are well-calibrated. False positive rates remain low because alerts trigger only when specific, understood conditions occur. However, recall can suffer—rules only catch known failure patterns, missing novel or complex fault signatures.

ML-based systems often achieve superior recall by detecting subtle patterns humans might miss. Studies across industries show ML approaches identifying faults 10-30% earlier than rule-based systems. However, this sensitivity can increase false positive rates, particularly during model training phases or when operational conditions shift unexpectedly.

The Real Cost of False Positives and False Negatives

False positives in fault detection aren’t merely inconvenient—they carry tangible costs. Unnecessary maintenance shutdowns reduce production throughput, waste labor resources, and can actually introduce new problems through excessive equipment handling. Organizations experiencing frequent false alarms often develop “alert fatigue,” where operators begin ignoring warnings, creating dangerous situations.

False negatives—failing to detect actual faults—pose even greater risks. Equipment failures can cascade, causing safety incidents, environmental damage, or extensive secondary damage to related systems. In critical industries, a single missed fault might result in millions of dollars in losses or, worse, threaten human lives.

The balance between these error types depends on context. In safety-critical applications, organizations accept higher false positive rates to minimize false negatives. In cost-sensitive operations, the equation shifts toward reducing unnecessary interventions.

🛠️ Implementation Realities: Complexity, Data, and Infrastructure

The practical challenges of implementing each approach differ significantly. Rule-based systems require deep domain expertise but relatively modest infrastructure. A team of experienced engineers can develop effective rule sets using standard industrial control systems, with implementation timelines measured in weeks or months.

ML-based systems demand different resources. Organizations need substantial historical data—ideally including labeled failure examples—data scientists with specialized skills, computational infrastructure for model training, and ongoing resources for model maintenance and retraining. Implementation timelines extend to months or years, particularly for complex industrial environments.

Data quality becomes paramount for ML approaches. These systems require clean, consistent, properly labeled data—requirements that expose deficiencies in many organizations’ data collection practices. Rules can function with sparse data, relying instead on expert knowledge to define thresholds and conditions.

Navigating the Integration Challenge

Integrating fault detection systems with existing infrastructure presents distinct challenges for each approach. Rule-based systems typically interface cleanly with legacy SCADA systems and programmable logic controllers, using established industrial protocols and communication standards.

ML systems often require modern data pipelines, edge computing infrastructure for real-time inference, and integration with cloud platforms for model training. Legacy equipment may lack the sensor density or data accessibility that ML approaches need to reach their potential.

The organizational change management aspect shouldn’t be underestimated. Operators comfortable with transparent rule-based alerts may resist “black box” ML predictions, requiring significant training and trust-building efforts to achieve successful adoption.

🎯 Finding the Sweet Spot: Hybrid Approaches

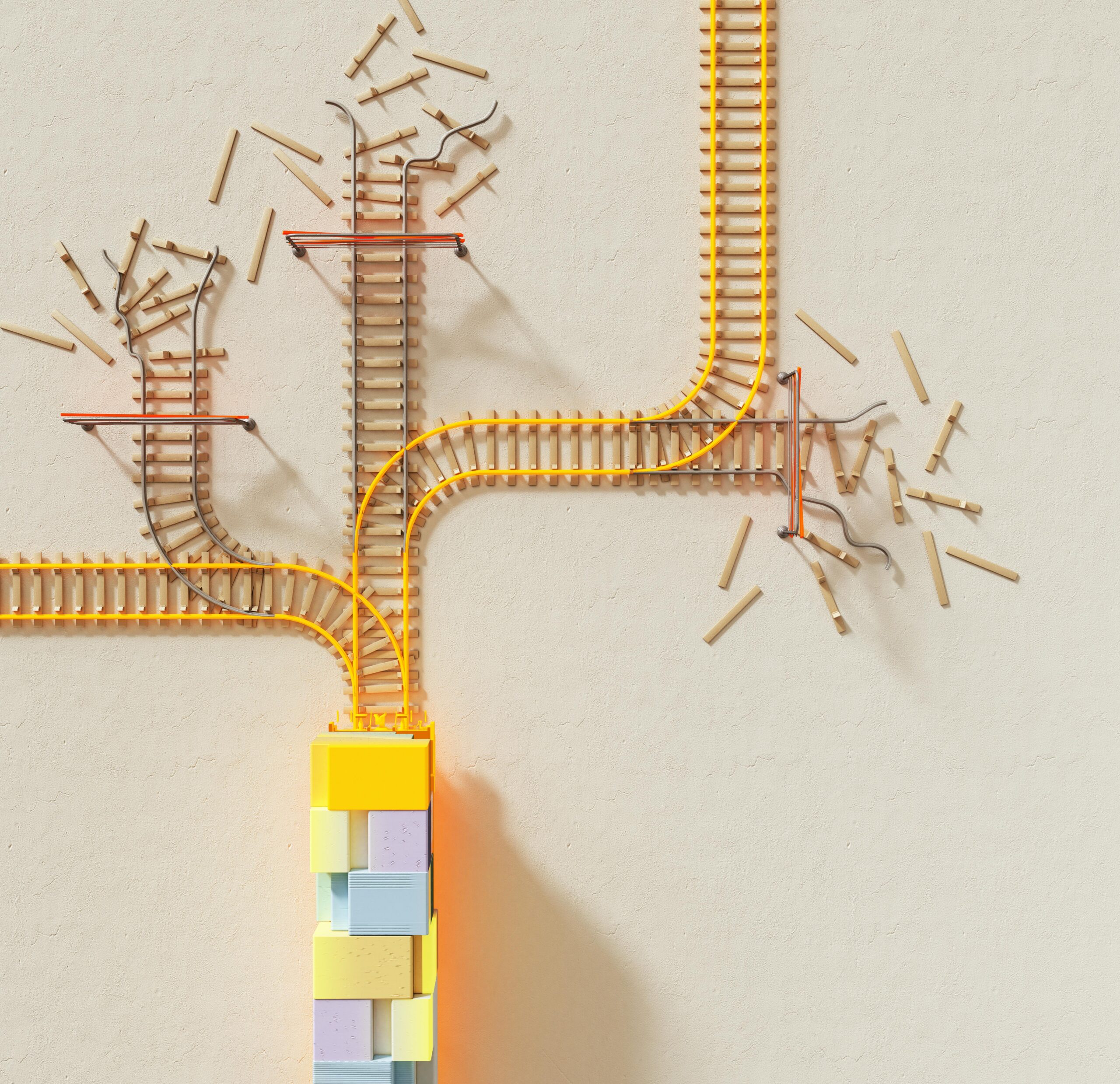

Forward-thinking organizations increasingly recognize that the rule-based versus ML debate presents a false dichotomy. Hybrid approaches that combine both methodologies often deliver superior results by leveraging the strengths of each while mitigating their respective weaknesses.

One effective hybrid strategy uses rule-based systems for well-understood failure modes while deploying ML models to catch complex, emerging, or subtle anomalies. This division of labor ensures reliable detection of known issues while expanding coverage to previously undetectable problems.

Another approach employs ML models to generate candidate alerts, which are then filtered through rule-based logic before reaching operators. This architecture reduces false positives by requiring both systems to agree before triggering interventions, dramatically improving precision without sacrificing the recall advantages of machine learning.

ML-Enhanced Rule Development

Machine learning can actually improve rule-based systems by analyzing historical data to suggest new rules or refine existing thresholds. This approach uses ML’s pattern recognition capabilities to inform human expertise rather than replace it, creating more effective rule sets than domain knowledge alone could produce.

Explainable AI techniques are bridging the interpretability gap, making ML models more transparent. Methods like SHAP (SHapley Additive exPlanations) and LIME (Local Interpretable Model-agnostic Explanations) reveal which features drive model predictions, providing insights that operators can understand and trust.

📊 Industry-Specific Considerations and Use Cases

Different industries face unique fault detection challenges that influence which approach proves most effective. Manufacturing environments with repetitive processes and well-characterized equipment often thrive with rule-based systems, particularly when process consistency is high and failure modes are understood.

The energy sector, particularly wind and solar installations, increasingly favors ML approaches. These systems operate across diverse geographical conditions with weather-dependent performance variations that make static rules less effective. ML models adapt to location-specific patterns, improving detection accuracy.

Telecommunications networks generate massive data volumes with complex interdependencies between components. ML systems excel at identifying subtle degradation patterns across network elements, predicting failures before they impact service quality. The data richness of telecom environments provides the fuel ML approaches need to demonstrate their full potential.

Automotive and Aerospace: Where Safety Meets Innovation

The automotive industry employs both approaches strategically. Critical safety systems often use rule-based detection for its reliability and regulatory acceptance, while predictive maintenance systems leverage ML to optimize service scheduling and reduce warranty costs.

Aerospace applications demand the highest reliability standards, making the interpretability of rule-based systems attractive for flight-critical functions. However, ML approaches are gaining ground in engine health monitoring and predictive maintenance, where their ability to detect subtle degradation patterns extends component life and improves safety margins.

💡 Making the Strategic Decision: Which Approach Fits Your Needs?

Selecting between rule-based and ML-based fault detection requires honest assessment of your organization’s circumstances, capabilities, and objectives. Several key questions should guide this decision-making process.

First, evaluate your data landscape. Do you have extensive historical data, including labeled failure examples? Is your data collection infrastructure reliable and comprehensive? ML approaches require affirmative answers to both questions. If data is limited or inconsistent, rule-based systems offer a more practical starting point.

Consider your team’s capabilities. Do you have access to data science expertise, either internally or through partners? Can you commit to ongoing model maintenance and retraining? Rule-based systems align better with traditional engineering skillsets, while ML demands specialized knowledge.

Assess the nature of your fault landscape. Are failures well-understood and relatively stable, or do you face evolving, complex failure modes that elude simple characterization? The former suggests rule-based approaches; the latter points toward machine learning.

Budget and ROI Considerations

Cost structures differ significantly between approaches. Rule-based systems typically have lower initial costs but may require more frequent manual updates as conditions change. ML systems demand higher upfront investment in infrastructure and expertise but can reduce ongoing maintenance costs through adaptation.

Return on investment depends on your operational context. If downtime costs are extreme—think continuous process industries or critical infrastructure—the superior early detection capabilities of ML systems can justify substantial investment. In lower-stakes environments, the simplicity and reliability of rules may optimize the cost-benefit equation.

🚀 The Future Landscape: Convergence and Evolution

The fault detection landscape continues evolving rapidly. Edge AI technologies are bringing ML inference closer to equipment, enabling real-time detection with minimal latency. AutoML platforms are democratizing machine learning, making it accessible to organizations without deep data science resources.

Digital twin technology is creating new possibilities for both approaches. Virtual replicas of physical assets allow rule refinement and ML model training in simulated environments, reducing the risk and cost of experimentation in production systems.

The convergence of physics-based modeling with data-driven ML approaches represents another frontier. These hybrid models incorporate engineering principles as constraints or features, combining domain knowledge with learning capabilities to achieve performance neither approach could deliver independently.

As industries embrace Industry 4.0 and IoT connectivity expands, the data foundation for ML-based fault detection strengthens. Simultaneously, advances in explainable AI are addressing the interpretability concerns that have limited ML adoption in regulated industries. The future likely belongs to intelligent systems that seamlessly blend rule-based reliability with ML-powered adaptability.

🎓 Building Organizational Readiness for Advanced Fault Detection

Successfully implementing either approach requires organizational preparation beyond technical considerations. Developing a culture that values data-driven decision-making creates the foundation for both rule-based optimization and ML deployment.

Investing in sensor infrastructure and data collection systems pays dividends regardless of which detection approach you choose. Better data enables more precise rule calibration and provides the fuel for ML algorithms. Treat data quality as a strategic asset, not merely an IT concern.

Training your workforce represents another critical investment. For rule-based systems, engineers need tools and methodologies for systematic rule development and maintenance. ML approaches require building data literacy across operations teams so they can effectively interpret and act on model predictions.

The path forward rarely involves wholesale replacement of existing systems. Instead, organizations should adopt evolutionary strategies—enhancing current rule-based approaches while piloting ML applications in specific use cases where they offer clear advantages. This gradual approach manages risk while building organizational capability and confidence.

Ultimately, the power of precision in fault detection comes not from choosing between rules and machine learning, but from understanding how each approach serves your specific operational needs. The most successful organizations will be those that thoughtfully combine both methodologies, creating detection systems that are simultaneously reliable, adaptive, and aligned with their strategic objectives. Whether you start with rules and evolve toward ML, or implement hybrid approaches from the outset, the goal remains constant: detecting faults earlier, more accurately, and more efficiently than ever before. 🎯

Toni Santos is a technical researcher and aerospace safety specialist focusing on the study of airspace protection systems, predictive hazard analysis, and the computational models embedded in flight safety protocols. Through an interdisciplinary and data-driven lens, Toni investigates how aviation technology has encoded precision, reliability, and safety into autonomous flight systems — across platforms, sensors, and critical operations. His work is grounded in a fascination with sensors not only as devices, but as carriers of critical intelligence. From collision-risk modeling algorithms to emergency descent systems and location precision mapping, Toni uncovers the analytical and diagnostic tools through which systems preserve their capacity to detect failure and ensure safe navigation. With a background in sensor diagnostics and aerospace system analysis, Toni blends fault detection with predictive modeling to reveal how sensors are used to shape accuracy, transmit real-time data, and encode navigational intelligence. As the creative mind behind zavrixon, Toni curates technical frameworks, predictive safety models, and diagnostic interpretations that advance the deep operational ties between sensors, navigation, and autonomous flight reliability. His work is a tribute to: The predictive accuracy of Collision-Risk Modeling Systems The critical protocols of Emergency Descent and Safety Response The navigational precision of Location Mapping Technologies The layered diagnostic logic of Sensor Fault Detection and Analysis Whether you're an aerospace engineer, safety analyst, or curious explorer of flight system intelligence, Toni invites you to explore the hidden architecture of navigation technology — one sensor, one algorithm, one safeguard at a time.